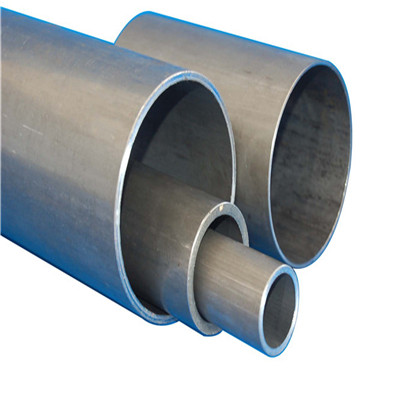

DIN1629 Carbon Seamless Steel Pipe

DIN 1629 is the standard specifies the Seamless Circular Tubes of Non Alloys Steels with Special Quality Requirements. Din 1629 seamless steel pipes application fields are: chemical plant, vessels, pipework construction and for common mechanical engineering purposes. Normally DIN 1629 standard are manufactured with no limiting working pressure values. Working temperature is limited below 300℃.

The main products of steel grade DIN 1629 are

- din1629 ST37.0

- din1629 ST44.0

- din1629 ST52.0

DIN 2391 ST 37 can be processed as hot rolled, cold rolled, cutting, grinding, machining and forming operations. It has high impact strength due to which it can be used under high impact prone outdoor applications as well.

DIN 1629 ST 52 is a low-cost Low Carbon Steel Tubes with max 022 % carbon content easy to form and shape. It is suitable for gas fusion welding, arc welding, flash butt welding, electric pressure welding and gas pressure welding. DIN 1629 part 3 is not only hard, but it also has high tensile properties, which is expected for structural components. It has good weldability properties with its pre-existing chemistry.

Chemical composition:

|

Steel Grade |

Type of deoxidization |

Chemical Composition, % by mass |

|||||

| Symbol | Material Number | C | P | S | N¹) |

Addition of nitrogen fixing elements |

|

|

St37.0 |

1.0254 | R | 0.17 | 0.040 | 0.040 | 0.009²) | – |

|

St44.0 |

1.0255 |

R |

0.21 | 0.040 | 0.040 | 0.009²) | – |

| St52.0³) | 1.0421 | RR | 0.22 | 0.040 | 0.035 | – |

Yes |

Mechanical properties:

|

Steel Grade |

Upper Yield Stress ReH for wall thickness, in mm, |

Tensile strength Rm N/mm² |

Elongation(%) A5 |

||||

|

Symbol |

Material Number | up to 16 | over 16 up to 40 |

over 40 up to 65 |

Longitudinal |

Transverse | |

|

St 37.0 |

1.0254 | 235 | 225 | 216 | 350²) to 480 | 25 | 23 |

| St 44.0 | 1.0256 | 275¹) | 265¹) | 255¹) | 420²) to 550 | 21 |

19 |

| St 52.0 | 1.0421 | 355 | 345 | 335 | 500²) to 650 | 21 |

19 |

| ¹) For cold f inished tube in the NBK condition (annealed above the upper transformation point under shielding gas or in a vacuum), minimum values of yield stress lower than these valued by 20N/mm² are permitted. ²) For cold finished tubes in the NBK condition, minimum values of tensile strength lower than these values by 10N/mm² are permitted. |

|||||||