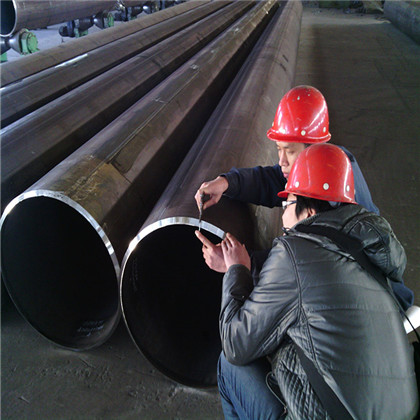

Large diameter thick wall straight seam double-sided submerged arc welded steel pipe

Standard: GB/T3091-2001、GB/T9711.1-2011、API

Outside Diameter: Φ325mm-Φ1820mm

Wall Thickness: 7-60mm

Material: Q235B、20#、X42-70、Alloy Steel, Stainless Steel

Test: The current non-destructive testing technologies include magnetic non-destructive testing, ultrasonic flaw detectors, radiographic testing to non-destructive testing, etc.

Large diameter thick wall straight seam double-sided submerged arc welded steel pipe are coiled from steel plates and need to be welded after the coiling is completed. Generally, three-step welding, pre-welding, external welding, and internal welding are carried out. Flaw detection is required after the welding is completed.

Large diameter thick wall straight seam double-sided submerged arc welded steel pipe is a steel pipe for oil and gas transportation pipelines with large consumption and high reliability. Submerged arc welding straight seam steel pipe unit, forming unit types include UOE, RBE, JCOE, etc. The main production process is qualified steel plate-plate edge chamfering-plate edge pre-bending-forming-JCOE forming-steel pipe joint continuous welding-pipe inner seam arc welding-pipe outer seam submerged arc welding-rounding and straightening-pipe end Chamfering and smoothing-ultrasonic inspection of weld seam-unqualified weld bead repair-weld bead X-ray inspection-hydraulic test-weld bead ultrasonic inspection-unqualified weld bead repair-pipe inner surface drying treatment-pipe inner surface rust removal treatment-pipe inner surface Anti-rust coating treatment-rust removal treatment on the outer surface of the tube-antirust coating treatment on the outer surface of the tube-finished product.