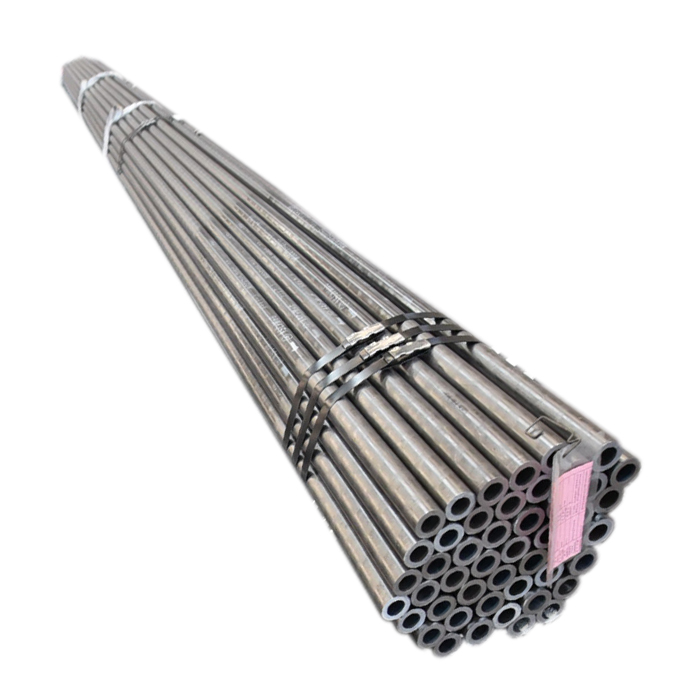

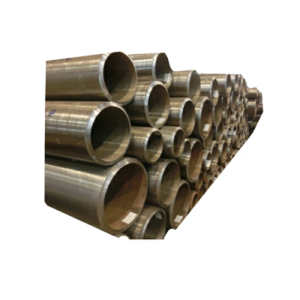

ASTM A213 T9 COLD DRAWN SEAMLESS HIGH PRESSURE BOILER TUBE

Specifications of ASTM A213 T9 Cold Drawn Seamless High Pressure Boiler Tube

| Equivalent Standards | EN 10216-2, ASTM A335, GOST 550-75 |

| Material | T9, S50400 |

| Equivalent Material | P9 |

| Type | Seamless |

| Specialized in | Large Diameter Size |

| Outer Dimensions | 6-2500mm; WT:1-200mm |

| Wall Thickness | Schedule 3mm to 15mm. |

| Length | max 1~12m |

| Schedule | STD, SCH40, SCH80 |

| Tubing End | Plain End, Beveled End, Treaded. |

| Standard | ASTM A213 T9, SA213 T9 (with IBR Test Certificate) |

| Sa 213 Gr T9 Specification / Sa213 T9 Specifications | ASTM A213 & ASTM A209 (T1 , Ta, T1b) BS/3059/90/PartII/620 & 622 DIN/17175/13CrMo44 DIN/17175/10CrMo910 DIN/17175/15Mo3 |

| Size | 6.35 mm OD to 610 mm OD |

| Sch. & Swg. | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg., 3.6 mm Thk |

| Thickness | 3-60mm |

| Tolerance | Cold drawn pipe: +/-0.1mm

Cold rolled pipe: +/-0.05mm |

| Craft | Cold rolled and Cold drawn |

| Type | Seamless / ERW / Welded / Fabricated |

| available in Form of | Round, Square, Rectangular, Hydraulic Etc. |

| Length | Single Random, Double Random & Cut Length. |

| Specialized in | ASME SA213 T9 Boiler Tube, SA213 T9 Heater Tube, SA213 T9 Heat Exchanger Tube |

| Additional Testing | NACE MR 0175, NACE TM0177, NACE TM0284, HIC TEST, SSC TEST, H2 SERVICE, IBR, etc. |

| Application | oiler, Heat Exchanger, Superheater and so on. |

T9 Alloy Steel Tube (SA213 T9, Chorme-Moly) is a consistent ferritic Alloy Steel Tube for high temperature administration. These T9 material including SA213 T9 Seamless Tube and Alloy Steel T9 Tube are appropriate for high temperature application, for example, twisting, flanging (vanstoning), and comparative framing activities, and for combination welding in the power business and petro-synthetic plants. SA213 T9 Alloy Steel Tubing is otherwise called ASTM A213 T9 chrome moly tube in view of the concoction cosmetics of Molybdenum (Mo) and Chromium (Cr).

Chemical Composition of ASTM A213 T9 Cold Drawn Seamless High Pressure Boiler Tube

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.15 max | 0.30-0.60 | 0.025 max | 0.025 max | 0.25-1.00 | 8.0-10.0 | 0.90-1.10 |

Mechanical Properties of ASTM A213 T9 Cold Drawn Seamless High Pressure Boiler Tube

| Tensile Strength , MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

| 415 min | 205 min | 30 min | 179 max |

Our advantages:

- Diverse products(Steel pipes, pipe fittings, other fittings)

- Any third party inspection is accepted by we company.

- Quick response in quotation, delivery, after-service.

- Focus on pipe & tube solution for project application.