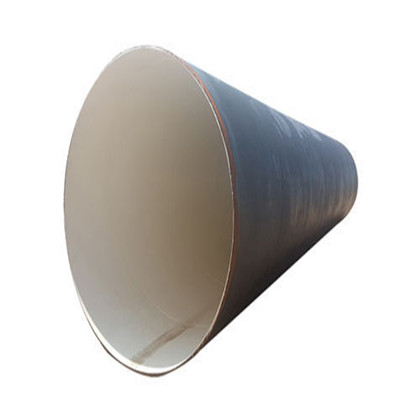

Large Diameter Heavy Wall Welded Steel Pipe

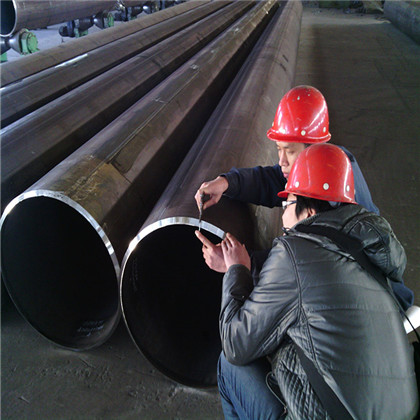

Large diameter heavy wall longitudinally welded steel pipes generally have a diameter above 325mm and are called large-diameter welded pipes. Large diameter heavy wall longitudinally welded steel pipes are double-sided submerged arc welding. Manual welding can also be carried out after the steel pipe is formed. The general inspection method is flaw detection. After the flaw detection is qualified, it can be shipped out. Unqualified products need to be re-welded. Large diameter heavy wall longitudinally welded steel pipes are generally suitable for liquid transportation, steel structure support, and piling. They are widely used in petrochemical, construction, water engineering, power industry, agricultural irrigation, urban construction, etc. The steel pipe should be able to withstand a certain internal pressure. If necessary, carry out a 2.5Mpa pressure test and keep it without leakage for one minute. The eddy current flaw detection method is allowed to replace the hydraulic test. The molding methods mainly include UOE, RBE, JCOE, etc., among which JCOE has the highest usage rate. The pipe end can also be threaded according to the customer’s requirements, which is also called threaded and unthreaded.