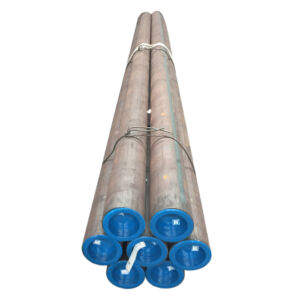

JIS G3456 STPT 410 Carbon Steel Pipes

Standard: JIS G3456 Carbon Steel Pipes for High Temperature Service

JIS G3456 STPT 410 Carbon Steel Pipes mainly used for piping at a temperature over 350℃.

JIS G3456 STPT 410 Carbon Steel Pipes Quick Details

Manufacture:Seamless or electric resistance welding process

Out Dimensions: 14mm-508mm

Wall Thickness: 2mm-60mm

Length: Fixed(6m,9m,12,24m) or normal length(5-12m)

Ends: Plain End, Beveled End, Treaded

Method of Manufacture

(1)JIS G3456 STPT 410 Carbon Steel Pipes are manufactured from coarse-grained killed steel by the seamless or electric resistance welding process

(2)When required by the purchaser, the pipe may be furnished with the bevel end.

Heat treatment of of JIS G3456 STPT 410 Carbon Steel Pipes

| Grade | Hot finished seamless steel pipe | Cold finished seamless steel pipe | Hot finished electric resistance welded steel pipe | Electric resistance welded steel pipe other than hot finished |

| STPT410 | As manufactured. However, low temperature annealing or normalizing may be applied, as necessary. | Low temperature annealed or normalized. | As manufactured. However, low temperature annealing or normalizing may be applied, as necessary. |

Low temperature annealed or normalized. |

Chemical Composition of JIS G3456 STPT 410 Carbon Steel Pipes

|

Grade |

Chemical Composition % |

||||

| C | Si | Mn | p |

S |

|

| STPT 410 | 0.30 max. | 0.10~0.35 | 0.30~1.00 | 0.035 max. |

0.035 max. |

Mechanical Properties of JIS G3456 STPT 410 Carbon Steel Pipes

| Letter symbol of grade | Mechanical Properties | |||||

| Tensile strength | Yield strength | Elongation % | ||||

| kgf/m㎡ {N/ m㎡} | kgf/m㎡ {N/ m㎡} | No.11 and No.12 test pieces | No. 5 test pieces | No. 4 test piece | ||

| Longitudinal | Transverse | Longitudinal | Transverse | |||

| STPT 410 | 42{412}min | 25{245} min | 25 min | 20 min | 19 min | 24 min |

Dimensions Tolerance of JIS G3456

| Division | Tolerances on outside diameter | Tolerances on wall thickness | Tolerance on deviation in wall thickness |

| Hot finished seamless steel pipe |

Up to 50 mm 【0.5mm | ≤Up to 4 mm 【0.5mm |

Up to and incl. 20 % of wall thickness |

| 50mm and over, up to 160mm 【1% |

|||

| 160mm and over, up to 200mm 【1.6mm |

≤4mm and over 【12.5% |

||

| 200mm and over 【0.8% | |||

| However, for pipes 350mm and over in diameter, the length of circumference may substitute as a basis for tolerances, In this case, the tolerances shall be 【0.5%. |

|||

| Cold finished seamless steel pipe and electric resistance welded steel pipe |

Up to 40mm 【0.3mm | ≤Up to 2 mm 【0.2mm |

– |

| 40mm and over 【0.8% | ≤2mm and over 【10% |

||

| However, for pipes 350mm and over in diameter, the length of circumference may substitute as a basis for tolerances. In this case, the tolerances shall be 【0.5% |

Testings

(1)Chemical analysis

(2)Tensile Test

(3)Flattening Test

(4) Bending Test

(5) Hydrostatic Test or Nondestructive Examination

Report

We will submit to the purchaser the report on the test results, method of manufacture, ordered dimensions, quantity and work lot number traceable to the manufacturing conditions, etc.