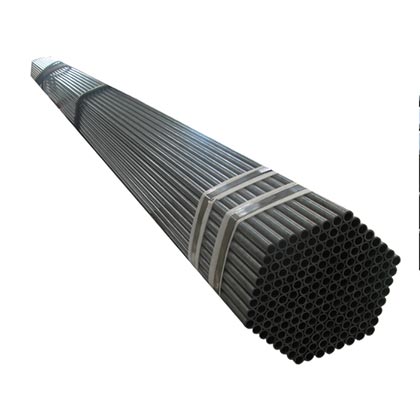

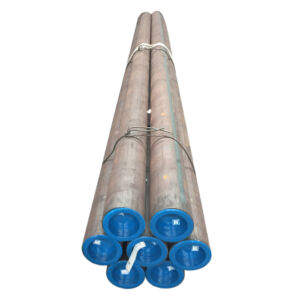

JIS G3455 STS 410 Seamless Carbon Steel Pipes for High Pressure Service

Standard:JIS G3455 Carbon Steel Pipes for High Pressure Service

JIS G3455 STS 410 Seamless Carbon Steel Pipes used for high pressure service at an approximate maximum temperature of 350℃

JIS G3455 STS 410 Seamless Carbon Steel Pipes Quick Details

Manufacture:Seamless process; Hot-finished,Cold-finished

Out Dimensions: 14mm-508mm

Wall Thickness: 2mm-60mm

Length: Fixed(6m,9m,12,24m) or normal length(5-12m)

Ends: Plain End, Beveled End, Treaded

Heat treatment of JIS G3455 STS 410 Seamless Carbon Steel Pipes for High Pressure Service

| Letter symbol of grade | Hot-finished seamless steel pipe |

Cold-finished seamless steel pipe |

| STS 410 | As manufactured. However, low temperature annealing of normalizing may be applied, as necessary. |

Low temperature annealed of normalized |

Chemical Composition of JIS G3455 STS 410 Seamless Carbon Steel Pipes for High Pressure Service

|

Grade |

Chemical Composition % | ||||

| C | Si | Mn | P |

S |

|

| STS 410 | 0.30 max. | 0.10~0.35 | 0.30~1.40 | 0.035 max. |

0.035 max. |

Mechanical Properties of JIS G3455 STS 410 Seamless Carbon Steel Pipes for High Pressure Service

| Letter symbol of grade |

Mechanical Properties |

|||||

|

Tensile strength |

Yield strength | Elongation % | ||||

| kgf/m㎡ {N/ m㎡} | kgf/m㎡ {N/ m㎡} |

No.11 and No.12 test pieces |

No. 5 test pieces |

No. 4 test piece |

||

| Longitudinal | Transverse | Longitudinal | Transverse | |||

| STS 410 | 42{412}min | 25{245} min | 25 min | 20 min | 19 min |

24 min |

Appearance

(1)The pipe are practically straight, and its both ends shall be at a right angle to its axis.

(2) The inside and outside surfaces of the pipe shall be well-finished and free form defects that are detrimental to practical use.

Testings

(1)Chemical analysis

(2)Tensile Test

(3)Flattening Test

(4) Bending Test

(5) Hydrostatic Test or Nondestructive Examination

Dimensions Tolerance of JIS G3455 Carbon Steel Pipes

| Division | Tolerances on outside diameter | Tolerances on wall thickness | Tolerances on wall thickness deviation |

| Hot-finished seamless steel pipe | 50mm Under 【0.5mm | ≤4mm Under +0.6mm -0.5mm ≤4mm or over +15% -12.5% |

Within 20% of wall thickness |

| 50mm or over 200mm to and excl. 【1.6mm |

|||

| 200mm of over 【0.8% | |||

| For the pipe 350mm of over, the tolerances on outside diameter may be determined by the measurement of the length of circumference. shall be 【0.5%. |

|||

| Cold-finished seamless steel pipe | 40mm Under【0.3mm | ≤2mm Under 【0.2mm |

– |

| 40mm of over 【0.8% | ≤2mm or over 【10% |

||

| For the pipe 350mm or over, the tolerances on outside diameter may be determined by the measurement of the length of circumference, In this case, the tolerances shall be 【0.5%. |

Marking

Each pipe having passed the inspection shall be marked with the following items. However, the smaller pipes of other pipes specified by the purchaser may be bundled together and marked for each bundle by a suitable means. In both cases, the order of arranging the marked items is not specified.

When approved by the purchaser, part of the items may be omitted.

(1) Letter symbol of grade(STS 410 )

(2) Letter symbol indicating the manufacturing process

(3) Dimensions

(4) Manufacture’s name or its identifying brand

(5) Letter symbol Z indicating the supplementary quality specification

Notes

The letter symbol indicating the manufacturing process shall be as follows, provided that the dash may be omitted leaving a blank.

Hot-finished seamless steel pipe – S – H

Cold-Finished seamless steel pips – S – C

Note

The dimensions shall be expressed as follows:

Nominal dia. x nominal wall thickness or outside dia. x wall thickness

Example : 50A 】Sch 80

Report

We will submit to the purchaser the report carrying the test results, method of manufacture, ordered dimensions, quantity and work lot number traceable to the manufacturing conditions, etc.