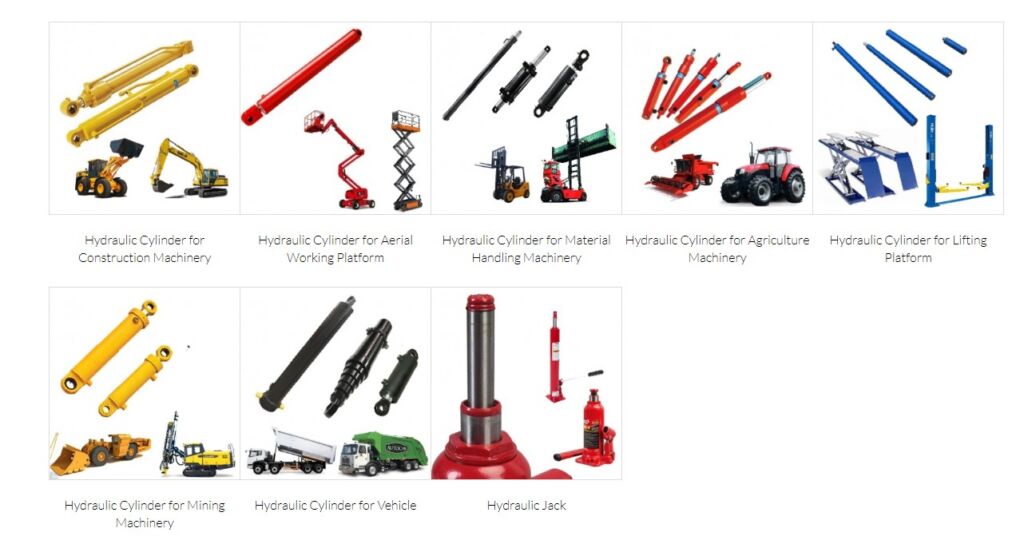

North Steel was established to offer precision steel to the hydraulic cylinder repair and hydraulic cylinder manufacturing industry. It manufactures a variety of precision cold drawn/ cold rolled seamless steel tubes and skived & roller burnished tubes for all kinds of hydraulic cylinders, covering construction machinery, agriculture machinery, mining machinery, material handling machinery, aerial working platform, lifting platform, vehicle, hydraulic jack and etc.

Hydraulic Cylinder Tube

Seamless hydraulic tubing is produced as a seamless tube by rolling and piercing bar stock. It then gets multiple cold-drawing reductions before a final cold draw guarantees tight dimensional tolerances and excellent surface finish. After final sizing of the tube through cold drawing it undergoes intermediate annealing and a dead-soft annealing process to meet requirements.

Size Range:

Cold Drawn Tube: I.D φ 16-220mm, WT 2-32mm

Cold Rolled Tube: I.D φ 16-82mm, WT 3.2-32mm

SRB Tube: I.D φ 50-250mm, WT 3-32mm

Executive Standard:

GB/T3639, Cold-drawn or cold-rolled precision seamless steel

GB/T1591, High strength low alloy structural steels

DIN2391, Seamless precision steel tubes

DIN2393, Welded Precision Steel Tubes

EN10305-1, Steel tubes for precision applications Part 1: Seamless cold drawn tubes

EN10305-2, Cold drawn steel tubes for precision applications Part 2: Welded cold drawn tubes

ASTM A519, Seamless Carbon and Alloy Steel Mechanical Tubing

ASTM A513, Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

According to customer’s specific requirements

Steel Grade: 20#, 45#, 25Mn, Q355B, Q345D ; ST45, ST52 ; E255, E355 ; 1020, 1026, 1045 and etc.

Delivery Condition:

Cold drawn/hard (+C) (BK)

Cold drawn and stress relieved (+SR) (BKS)

Advantages:

Adopt quality hydraulic cylinder-standard raw material from leading mills

High precision with tight allowance

No defects on internal surface

High concentricity and small wall thickness tolerance

High straightness

Hydraulic Cylinder Tube Size:

|

Processing Type |

ID(mm) | Length(mm) | Straightness(mm) | tolerance(mm) | Roughness(μm) |

|

Cold Drawn |

16-220 | ≤12 | 0.2-0.5/1000 | As per request | 0.8-1.6 |

| Cold Rolled | 16-82 | ≤12 | 0.2-0.5/1000 |

≤0.8 |

|

| Skived and Roller Burnished | 50-250 | ≤6 | 0.2-0.3/1000 | H8-H9 |

≤0.4 |

Chemical Composition:

|

Steel Grade |

C | Si | Mn | P | S | Cr | Ni | Cu | V | Al |

|

20# |

0.17-0.23 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.30 | ≤0.25 | ||

|

45# |

0.42-0.50 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.30 | ≤0.25 | ||

|

Q355B |

≤0.20 | ≤0.50 | ≤1.70 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.50 | ≤0.30 | ≤0.15 | |

|

Q345D |

≤0.18 | ≤0.50 | ≤1.70 | ≤0.030 | ≤0.025 | ≤0.30 | ≤0.50 | ≤0.30 | ≤0.15 | ≥0.015 |

| 25Mn | 0.22-0.29 | 0.17-0.37 | 0.70-1.0 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.30 |

≤0.25 |

||

| 1026 | 0.22-0.28 | 0.15-0.35 | 0.60-0.90 | ≤0.040 |

≤0.050 |

|||||

| ST45 | ≤0.21 | ≤0.35 | ≥0.4 | ≤0.025 |

≤0.025 |

|||||

| E255 | ≤0.21 | ≤0.35 | 0.40-1.10 | ≤0.025 | ≤0.025 |

|

||||

| E355 (ST52) | ≤0.22 | ≤0.55 | ≤1.6 | ≤0.025 | ≤0.025 |

≥0.02 |

Mechanical Properties:

|

Delivery Condition |

Cold Finished Hard (+C/ BK) | Cold Finished and Stress Relieved (+SR/ BKS) | ||||

|

Steel Grade |

Tensile Strength

(Mpa) |

Elongation

(%) |

Tensile Strength

(Mpa) |

Yield Strength

(Mpa) |

Elongation

(%) |

Impact Value (-20℃) |

| 20# / 1020 / E255 / ST45 | ≥580 | ≥8 | ≥580 | ≥480 | ≥15 |

– |

|

45# / 1045 |

≥680 | ≥5 | ≥630 | ≥520 | ≥12 | – |

| Q355B | ≥660 | ≥8 | ≥620 | ≥520 | ≥15 |

– |

|

Q345D |

≥660 | ≥8 | ≥620 | ≥520 | ≥15 | ≥27 |

|

25Mn (1026) |

≥640 | ≥8 | ≥620 | ≥510 | ≥15 |

– |

| E355 (ST52) | ≥680 | ≥8 | ≥650 | ≥580 | ≥15 |

≥27 |

Application: