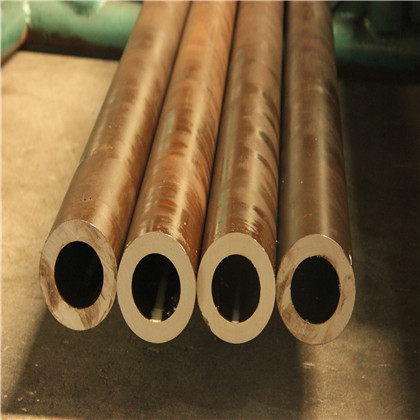

Geological Drilling Tube

Size Range: O.D 30-139.7 mm, WT 3-19mm

Executive Standard:

GB/T9808 Seamless Steel Tubes for Drilling

GB/T 16950, Geological core drilling tools

DIN2391, Seamless precision steel tubes

EN10305-1, Steel tubes for precision applications Part 1: Seamless cold drawn tubes

ASTM A519, Seamless Carbon and Alloy Steel Mechanical Tubing

DCDMA, Diamond Core Drilling Manufacturers Association

BS4019, Specification for rotary core drilling equipment

JIS G3465, Seamless Steel Tubes for Drilling

According to customer’s specific requirements

Steel Grade: 45MnMoB, 30CrMnSiA, 30CrMo, 42CrMo, 40Mn2 ; 34CrMo4, 42CrMo4 ; 4130, 4135, 4140, 1541 and etc.

Delivery Condition:

Cold drawn and stress relieved (+SR) (BKS)

Normalized (+N) (NBK)

Quenched and Tempered (QT)

Advantages:

Excellent microstructure

High straightness

Low residual hoop stresses

Tight tolerances, low eccentricity

Dimensional Range:

|

SIZE |

Wireline Drill Rod | SIZE | Casing | ||

|

Outer Diameter (mm) |

Inner Diameter

(mm) |

Outer Diameter

(mm) |

Inner Diameter (mm) |

||

|

Nom. |

Nom. | Nom. | Nom. | ||

| A | 44.45 | 35.05 | AW | 57.1 |

48.4 |

|

B |

55.55 | 46.05 | BW | 73.0 | 60.3 |

| N | 69.85 | 60.45 | NW | 88.9 |

76.2 |

|

H |

88.90 | 77.80 | HW | 114.3 | 101.6 |

| P | 114.30 | 101.60 | PW | 139.7 |

127.0 |

| S | 139.70 | 125.50 | |||

|

SIZE |

Outer Tube |

Inner Tube | ||

|

Outer Diameter (mm) |

Inner Diameter

(mm) |

Outer Diamete

(mm) |

Inner Diameter (mm) |

|

| Nom. | Nom. | Nom. |

Nom. |

|

|

A |

46.05 | 36.50 | 32.54 | 28.58 |

|

B |

57.15 | 46.05 | 42.85 |

38.10 |

| N | 73.03 | 60.33 | 55.58 |

49.99 |

|

H |

92.08 | 77.80 | 73.03 | 66.80 |

| P | 117.48 | 101.60 | 95.25 |

88.90 |

| S | 142.88 | 125.50 | 117.00 |

111.00 |

Chemical Composition:

|

Steel Grade |

C | Si | Mn | P | S | Cr | Mo | B |

|

45MnMoB |

0.43-0.48 | 0.17-0.37 | 1.05-1.35 | ≤0.020 | ≤0.015 | 0.20-0.25 | 0.001-0.005 | |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.040 | ≤0.040 | 0.80-1.10 |

0.15-0.25 |

|

|

1541 |

0.36-0.44 | – | 1.35-1.65 | ≤0.040 | ≤0.050 | |||

|

30CrMnSiA |

0.28-0.34 | 0.90-1.20 | 0.80-1.10 | ≤0.020 | ≤0.015 | 0.80-1.10 |

|

|

|

4140 |

0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.040 | ≤0.040 | 0.80-1.10 |

0.15-0.25 |

Mechanical Properties:

|

Steel Grade |

Deliver Condition | Min Tensile Strength

(Mpa) |

Min Yield Strength

(Mpa) |

Min Elongation

(%) |

Hardness

(HRC) |

|

45MnMoB |

Normalizing(+N) | 790 | 600 | 14% |

– |

|

4130 |

Stress relieving(+SR) | 813 | 690 | 15% | ≥24 |

| 1541 | Stress relieving(+SR) | 813 | 690 | 15% |

≥24 |

|

30CrMnSiA |

Quenched and tempered(QT) | 850 | 750 | 14% |

26 – 31 |

| 4140 | Quenched and tempered (QT) | 950 | 850 | 14% |

28 – 33 |