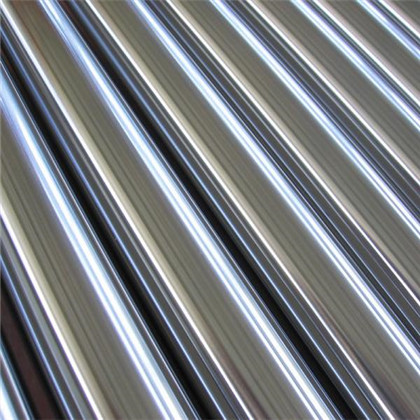

Hard Chrome Plated Shafts /Chrome Plated Bar with material CK45, SAE 1045, 4140 for Hydraulic Pistion Rod

Hard chrome plated shafts are known as Chrome plated rods or chrome plated bar also, they are usually used to manufacturing or repairing the hydraulic piston shafts. This product is widely used for most piston shaft applications in hydraulic and pneumatic cylinders.

Our hard chrome plated shafts are manufactured from round steel bar through high precision polishing, and chrome plated with a certain thickness, the thickness of chrome plated layer is usually min. 20 microns.

Detailed Product Description

Materials:

As the leading chrome plated bar supplier, our factory can produce chrome plated shafts in wide range of materials as carbon steel and stainless steels. The most popular steel grades of carbon steel chrome plated shafts are JIS S45C, SAE1045, AISI 1045 / 1050, DIN CK45.

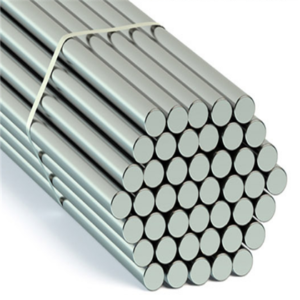

Size range:

We can manufacture hard chrome plated shafts with size range from external diameter 6 mm to 800 mm.

We supply both metric size chrome plated shafts and imperial sizes chrome plated bar.

Packing:

Our chrome plated shafts usually is packed with plastic sleeves or paper tubes. Also we can provide packing method of wooden cases on customers’ requests.

Chrome plated thickness

The thickness of the chrome plated layer can be 10 microns to 50 microns. And the most popular requirements is that the chrome layer of the chrome plated shaft is min. 20 microns.

Applications

Chrome plated shafts are usually used together with honed tubes for manufacturing or repairing the hydraulic cylinders or pneumatic cylinders. Beside this, the chrome plated rods also are widely used as shafts of various machines, where high precision and high smooth surface is required.

As the high quality China honed tube & chrome plated bar manufacturer, our factory also produces honed tubes and chrome plated hollow bars,

our products are exported to customers in many countries abroad, and gained very good reputation in the field.

Detailed Description

1.CHEMICAL COMPOSITION

| Material | C% | Mn% | Si% | S% | P% | V% | Cr% |

| Ck45 | 0.42-0.50 | 0.50-0.80 | 0.04 | 0.035 | 0.035 | ||

| ST52 | 0.22 | 1.6 | 0.55 | 0.035 | 0.04 | ||

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.10-0.50 | 0.035 | 0.035 | 0.10-0.20 | |

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.80-1.10 |

2.MECHANCIAL PROPERTIES

| Material | T.S N/MM2 | Y.S N/MM2 | E%(MIN) | CHARPY | CONDITION |

| CK45 | 610 | 355 | 15 | >41J | NORMALIZE |

| CK45 | 800 | 630 | 20 | >41J | Q + T |

| ST52 | 500 | 355 | 22 | NORMALIZE | |

| 20MnV6 | 750 | 590 | 12 | >40J | NORMALIZE |

| 42CrMo4 | 980 | 850 | 14 | >47J | Q + T |

| 40Cr | 1000 | 800 | 10 | Q + T |

3. SUPPLY CONDITION

Ground and chrome plated

4. CHROME THICKNESS

20 to 30 micron

5. SURFACE ROUGHNESS

Ra≤0.2 micron and Rt≤2 micro

6. TOLERANCES ON DIA

ISO f7 on the diameter

7.OVALITY

Half of the tolerance ISO f7

8. STRAIGHTNESS

≤0.2MM/M

9. SURFACE HARDNESS

850-1150HV (vickers 100g)

10.COHESION

No cracks,breaking or detaching after thermic shock(warming up at 300 celsius degrees and cooling

in water)

11 .POROSITY

Test according to ISO 1456/1458 and result yaluation according to ISO 4540 rating 8-10

12 CORROSION RESISTANCE

Test in natural salt spray according to ASTM B 117-72hours

Results evaluation according to ISO 4540 RATING 7-10

13. WELDABILITY

Good

14. PACKING

Anti rust oil to be applied on material and each rod to be packed in paper sleeve

15. CERTIFICATE

All certificate related with material heat treatment and plating is required.

From 2017, we established an intelligent workshop with all automatic machined. There are five lines only for producing exported products. The new workshop is executing 6S strictly. The production capacity will be 1500 tons per month.