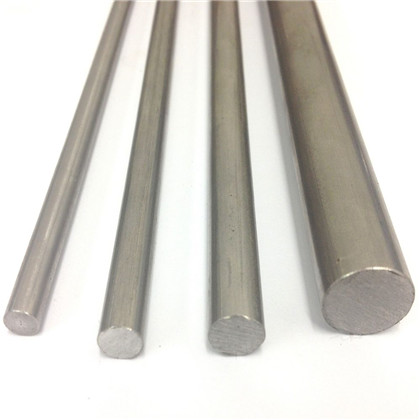

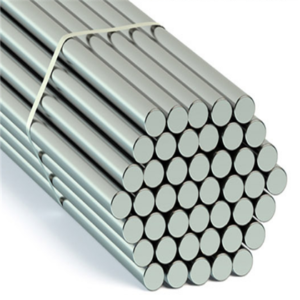

Cold Drawn Round Steel Bar /Cold Rolled Steel Bar / Steel Billet Steel Rod

Cold finished steel is essentially hot rolled steel that has further processing. Cold finished steel, also known as cold rolled, is typically produced as turned bars or cold drawn bars. Cold drawing hot rolled bars is accomplished by pulling (drawing) a bar through a die which is smaller than the incoming hot rolled size. The cold working process improves the dimensional tolerances of the bar, the straightness, the surface appearance as well as enhancing the physical properties of the steel.

Size & Roundness: Cold rolled steel has tighter size and roundness tolerances.

Straightness: The straightness is more precise than hot rolled steel.

Surface Finish: Cold finished steel is smooth and can be used for a variety of applications.

Mechanical Properties: The need for heat treatments are often eliminated due to the increased yields and tensile strength of cold finished steel.

Machinability: When using lower carbon grades, the machinability is improved, which leads to a better tool life.

Turning hot rolled bars is a cold machining process, which removes the surface of the hot rolled bars, improving their dimensional control while removing superficial features of the hot rolled bars which may be detrimental to the surface of the parts produced.

While most industries, like construction, utilize cold rolled steel. there are common applications for this steel such as:

- Gears and shafts

- Oil and water well shafting

- Industrial buildings

- Products which demand a defect-free surface

All North Steel cold drawn bars are also produced with our proprietary surface inspection equipment. cold-finished-cd-racksEddy current, roto – bar testing or mag testing are all available and used as required. The modification of the ultimate tensile strength, the yield strength, and elongation of the bars assists by improving machinability and chip formation.

Standard: ASTM A29, ASTM A108, JIS G4105

Grade: 45#, A3, 20Cr, 40Cr, 20CrMo, 40CrMo, 20Mn2A, 42CrMo, 20MnSi, 35CrMo, HG3, Q215, Q235, B16, 25Cr2MoVa, 60Si2MnA, 55CrSiA, 16Mn, 40Mn, S45C, SAE1045, CK45, SCM440, SAE4140; 1.7225

Size: Ф4.5—Ф70

Usage: Hardware tools, auto parts, standard parts, fasteners, general shaft, machinery manufacturing, light industry, hardware, standard parts, bicycles, automobiles, motorcycles, textile machinery, transformers and other machinery industries.

BENEFITS

- Improved dimensional tolerances

- Improved straightness capability

- Minimizes stock removal improving equipment performance and tool life

- 100% surface inspected to ASTM A-108 or better tolerances

- Improved mechanical properties aiding machinability and strength for applications

- Available in round, square, hexagon and profile shapes