ASTM A519 Carbon And Alloy Steel Seamless Mechanical Tubing

ASTM A519 Seamless mechanical tubing is manufactured from carbon and alloy steels for structural or other mechanical purposes involving machining or heat treating, where close tolerances, smooth finish, or definite physical properties are important factors. ASTM A519 specification covers for several grades of carbon and alloy steel mechanical tubing, either hot-finished or cold-finished.

Application:

- For mechanical engineering

- For mechanical and pressure use,and also for transporting steam,water,gas and etc.

Size range(mm):

- Out diameter:10-324mm

- Wall Tickness:1-30mm

- Length:14000mm max

Steel grade and Chemical composition (%) of ASTM A519:

| Grade | C | Mn | P≤ | S≤ | Si | Cr | Mo |

| 1008 | ≤0.10 | 0.30-0.50 | 0.040 | 0.050 | – | – | – |

| 1010 | 0.08-0.13 | 0.30-0.60 | 0.040 | 0.050 | – | – | – |

| 1018 | 0.15-0.20 | 0.60-0.90 | 0.040 | 0.050 | – | – | – |

| 1020 | 0.18-0.23 | 0.30-0.60 | 0.040 | 0.050 | – | – | – |

| 1025 | 0.22-0.28 | 0.30-0.60 | 0.040 | 0.050 | – | – | – |

| 1026 | 0.22-0.28 | 0.60-0.90 | 0.040 | 0.050 | – | – | – |

| 4130 | 0.28-0.33 | 0.40-0.60 | 0.040 | 0.050 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.75-1.00 | 0.040 | 0.050 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

Mechanical Properties of ASTM A519:

| Grade | Condition | MPa Tenslle Point | Yield Point | Elongation |

| 1020 | CW | ≥414 | ≥483 | ≥5% |

| SR | ≥345 | ≥448 | ≥10% | |

| A | ≥193 | ≥331 | ≥30% | |

| N | ≥234 | ≥379 | ≥22% | |

| 1025 | CW | ≥448 | ≥517 | ≥5% |

| SR | ≥379 | ≥483 | ≥8% | |

| A | ≥207 | ≥365 | ≥25% | |

| N | ≥248 | ≥379 | ≥22% | |

| 4130 | SR | ≥586 | ≥724 | ≥10% |

| A | ≥379 | ≥517 | ≥30% | |

| N | ≥414 | ≥621 | ≥20% | |

| 4140 | SR | ≥689 | ≥855 | ≥10% |

| A | ≥414 | ≥552 | ≥25% | |

| N | ≥621 | ≥855 | ≥20% |

Please note the meaning of below abbreviation in table 2:

- HR—-Hot Rolled

- CW—-Cold Worked

- SR—-Stress Relieved

- A—-Annealed

- N—-Normalized

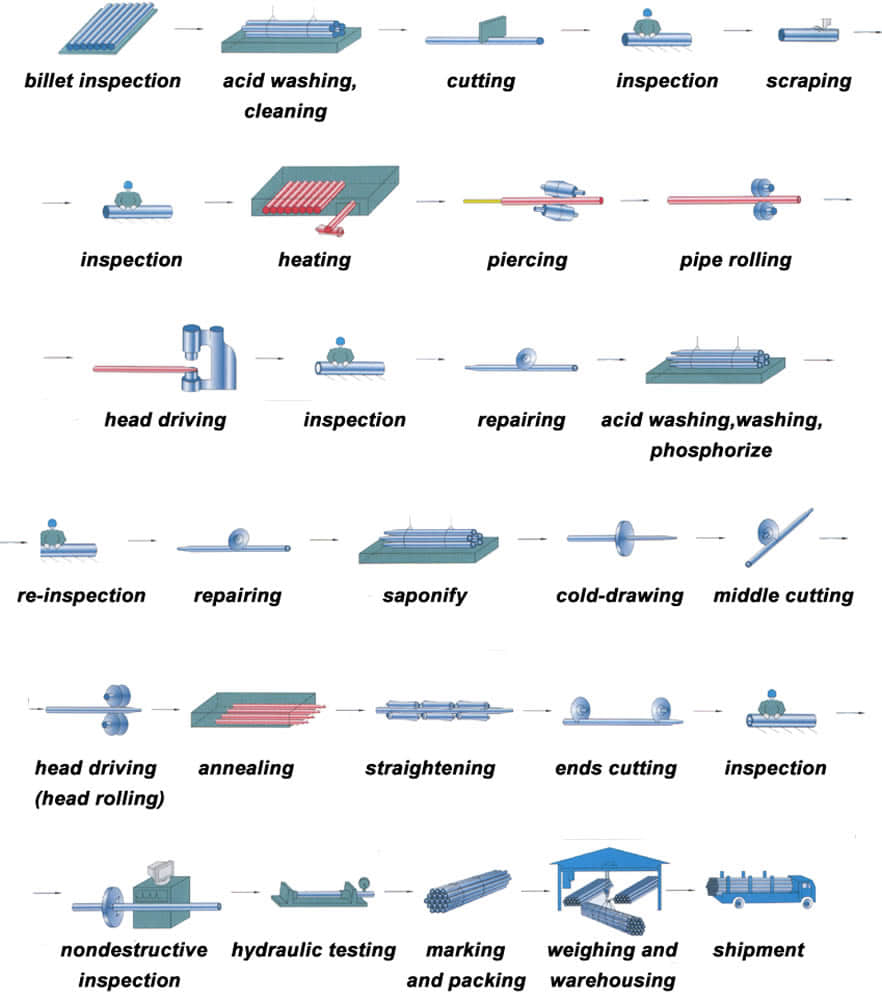

Process

Cold drawn seamless steel tube deformed process

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn 1018/1026 steel tube which offers uniform tolerances, enhanced machinability and increased strength and tolerances compared to hot-rolled products.

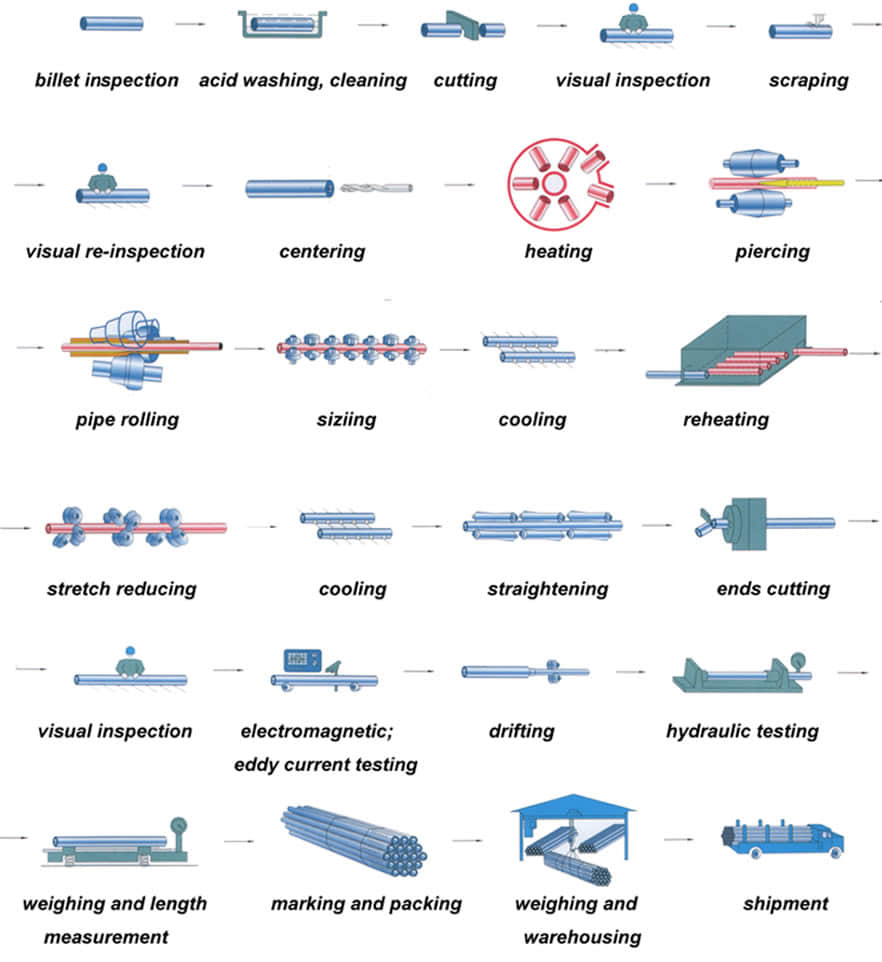

Hot rolled seamless steel pipe deformed process

Hot-rolled seamless steel pipe production base deformation process can be summarized as three stages: perforation, extension and finishing.

Inspection

Chemical composition inspection, mechanical properties test(tensile strength,yield strength, elongation, flaring, flattening, bending, hardness, impact test), surface and dimension test,no-destructive test, hydrostatic test.

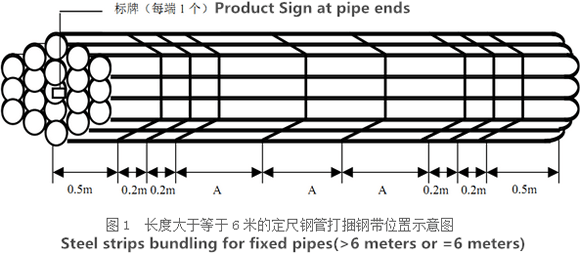

Packing

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

- Plastic caps plugged at the two sides of pipe ends

- Should be avoided by the steel strapping and transport damage

- Bundled signs should be uniform and consistent

- The same bundle(batch) of steel pipe should be came from the same furnace.

- The steel pipe has the same furnace number, the same steel grade, the same specifications.