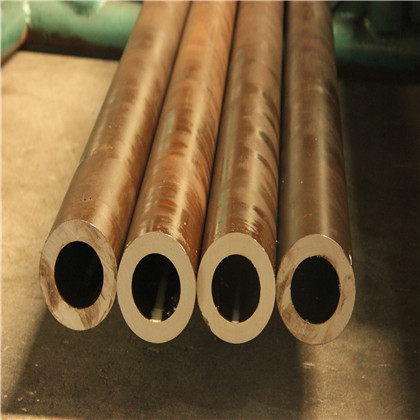

ASTM A519 4130 Seamless Pipe

Chromoly is specified by the “SAE” Society of Automotive Engineers. the Alloy elements of 4130 are chromium and molybdenum, this is why its often called chromoly or cromo. Chromoly has an excellent strength to weight ratio, is easily welded and are considerably stronger and harder than standard 1020 mild seamed and DOM tube steels.

Its performance is much higher than the average of seamless steel tubes, because the steel contains Cr more inside, alloy seamless pipe, its high temperature, low temperature resistance, corrosion resistance is smaller than other seamless.

Especially, it need to do the quenched & tempered and has a high technical requirements. so alloy tube in the petroleum, chemical, electric power, boiler and other industries use more widely.

Chemical composition (%)

| Grade | C | Mn | P | S | Si | Cr | Mo |

| 4130 | 0.28-0.33 | 0.40-0.60 | 0.035 | 0.04 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

- 41 means a low alloy steel containing 1 % chromium and 0.2 % molybdenum.

- 30 means a carbon content of 0.30%.

- In addition there will be around 0.2-0.5 % silicon, 0.5-1.0 % manganese, and under 0.1 % of each of a dozen or so other elements whose presence is unavoidable.

- The remaining 97-98 % is iron.

Mechanical properties (Mpa)

| Grade Designation | Condition | Ultimate Strength | Yield Strength | Elongation in 2 in.or 50mm,% | Rockwell,Hardness B Scale | ||

| ksi | Mpa | ksi | Mpa | ||||

| 4130 |

HR |

90 | 621 | 70 | 483 | 20 | 89 |

|

SR |

105 | 724 | 85 | 586 | 10 | 95 | |

| A | 75 | 517 | 55 | 379 | 30 |

81 |

|

| N | 90 | 621 | 60 | 414 | 20 |

89 |

|

4130 chromoly tubing began its first use in the aircraft industry. Race chassis builders began using the tubing for its strength to weight ratio.

4130 tubing is used for anything from bicycle frames, AK-47 receivers, tubular chasis, suspension parts, aircraft parts and air frames etc… Ive used cromo for suspension components, cages / tube chassis and machined parts.

Application Of 4130 & 4130 Pipe & Pipe Fittings

- This alloy is used for manufacturing ball and roller bearings.

- This alloy is also good for manufacturing gears due to their heat treatment property.

- It is used for rock-crushing machinery and automotive parts.

- It is used for manufacturing structural parts of aircraft.

- The main use of this alloy is in the field of resistance welding.

- It is used for cutter tools such as drills, taps, milling cutters, etc.