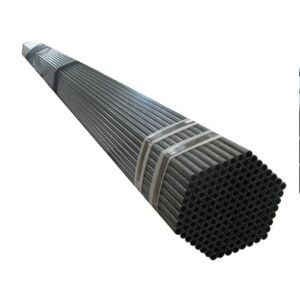

Seamless Carbon Steel Pipe ASTM A106

The term carbon steel pipe can be used to describe a wide range of metal tubular goods whose main alloying element is carbon in a range of 0.12%-2%. Apart from carbon elements like chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium & zirconium can be added to attain respective alloying effect.

For an example A333 grade 6 pipe has high tensile strength and impact properties used at low temperatures application as compared to A106 Grade B pipe with low tensile strength and used at room temperatures or higher temperatures. This is achieved by addition of manganese above the 0.9%, which is limited to 0.65% in A106 pipe.

In general, a pipe is referred as a carbon steel pipe when the maximum specified content of Manganese – 1.65%, Silicon – 0.6% & copper 0.6 % does not exceed the limit prescribed.

Carbon steel pipe are further divided into four categories:

Low carbon steel pipe – Carbon content 0.55-1.05%

Medium carbon steel pipe- Carbon content 0.25-10.6%

High carbon steel pipe- Carbon content 0.9-2.5%

Super High carbon steel pipe- Carbon content 2.5-3.0%

As the Carbon content increases, high carbon steel pipe can become harder and stronger by quenching and tempering with lower ductility.High carbon steel pipe if not heat treated, may result into low weld ability & low melting point.Large diameter pipe used for water transportation and general transit are made of carbon steel.

Heat Treatment

Carbon Steel pipe can be heat treated in various ways as listed below.

Normalising

Annealing

Quenching

Quenching and Tempering

Austempering

Spherodizing

Seamless carbon steel pipe (SMLS) is formed by drawing a solid billet over a piercing rod to create the hollow shell, without welding or seam. It is suitable for bending and cutting. The advantage of seamless steel is the ability of withstanding higher pressure.

For ASTM A106 seamless carbon steel pipe could transport fluids or gasses at high temperature and pressure levels, with 3 grades A, B, C, most common used ASTM A106 Grade B is widely used in the projects of oil and gas refineries, power plants, petrochemical plants, boilers. Pipe ordered under this specification shall be suitable for bending, for flanging, for welding, and for similar forming operations. A full range of SA/A106 stock is available in Schedules 10 through 160, STD, XS, XXS. Unscheduled wall thicknesses available up to 4 inches.

Black steel Pipe & Black Steel Tube

Standard: ASTM A106, Grade A, B, C

Size: NPS 1/8 to NPS 48

Dimension: Sch10/ Sch160 as ASME B36.10M

Length: Single random, Double random, 5.8m, 6m, 11.8m, 12m or as customers’ requirement

ASTM A106 Seamless Carbon Steel Pipe Chemical Composition

|

Steel Grade |

C, max.% | Mn % | P, max | S, max | Si, min | Cr, max | Cu, max | Mo, max | Ni, max |

V, max |

|

Grade A |

0.25 | 0.27 – 0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 |

0.08 |

|

Grade B |

0.30 | 0.29 – 1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 |

0.08 |

| Grade C | 0.35 | 0.29 – 1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 |

0.08 |

ASTM A106 Seamless Carbon Steel Pipe & black steel pipe Mechanical Property

|

Grade |

Tenssile Test MPa or N/mm2 |

Remarks (Similar to JIS) |

|

|

MIn. Yield Point |

Tensile Strength |

||

|

Gr A |

205 | 330Min |

(STPG370) |

|

Gr B |

240 | 415Min |

(STPG410) |

|

Gr C |

275 | 485Min |

(STPG480) |

ASTM A106 Seamless Carbon Steel Pipe Dimension Tolerances

|

Pipe Type |

Pipe Sizes |

Tolerances |

|

|

Cold Drawn |

OD |

≤48.3mm | ±0.40mm |

|

≥60.3mm |

±1%mm |

||

| WT |

±12.5% |

||

All the materials we used are ultra-hard and thick, and all the wooden cases and pallets we used are fumigation-free.

- Waterproof Paper Winding+PVC Film+Strap+Wooden Pallet

- Waterproof Paper Winding+PVC Film+Strap+Wooden Case

North Steel adopts standard export shipping packaging and bundles steel strips according to the size of the carbon steel pipe. According to our delivery experience, a 20-foot container can hold 22 tons of carbon steel, and a 40-foot container can hold 25 tons of carbon steel. For larger orders, we use bulk vessels to transport you, and the price is cheaper. Also, we can customize the packaging according to the needs of customers.