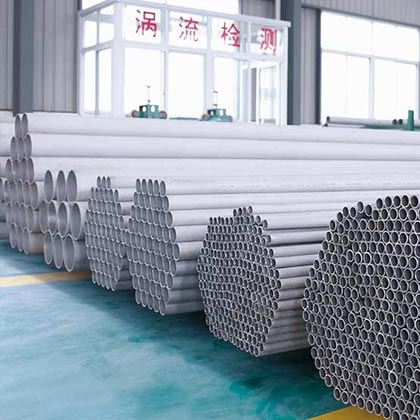

Seamless Stainless Steel Pipe/ Tubo sin soldadura de acero inoxidable

Seamless stainless steel pipe is made of steel ingot by piercing and then made by hot rolling, cold rolling or cold drawing.

1. Seamless Hot Rolling Processes

Round Pipe Billet → Heating → Perforation → Three Roll Skew Rolling, Continuous Rolling or Extrusion → Off Pipe → Sizing (Or Reducing Diameter)→ Cooling → Billet → Straightening → Water Pressure Test ( Or Flaw Detection) → Marking → Storage

2. Seamless Cold Rolling (Cold drawn) Processes

Round Pipe Billet → Heating → Perforation → Head → Annealing → Pickling → Oil (Copper) → Multi Pass Drawing (Cold Rolling) → Billet → Heat Treatment → Straightening → Water Pressure Test → Marking → Storage

Application: Seamless stainless steel pipe is widely used in boilers, central air conditioning, steel structure, machining, pipeline gas, fire protection, petroleum, chemical industry, medical, power and other industry fields, with high temperature resistant, low temperature resistant, corrosion.

Main Standard: ASTM A213, ASTM A312, ASTM A269

Main Grade: 304, 304L, 316, 316L, 321, 310, 310S, 347, 347H, 904L, 2205; 1.4301, 1.4306, 1.4401, 1.4404, 1.4541, 1.4845, 1.455, 1.4912, 1.4539

Outer Diameter: 6-325mm

Wall Thickness: 0.5-35mm

Length: Random

Surface Treatment: pickling or as customers’ requirement

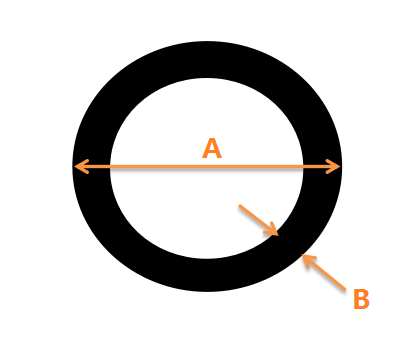

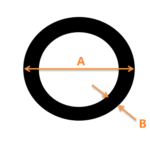

How is it Measured? Outer Diameter (A) X Schedule or Wall Thickness (B) X Length

PS: Advantages Of Seamless Tubes & Pipes

A. Heavy and thick wall thickness

B. No weld seam. Generally be considered as better properties and corrosion resistance

C. Better ovality, or roundness

| Type | Grade of Steel | Size | Standard | ||||

| GB | ASTM | JIS | Germany | ||||

| DIN17006 | DIN17007 | ||||||

| Seamless Stainless Steel Pipe | 0Cr18Ni9 | 304/S30400 | SUS304 | X5CrNi18-10 | 1.4301 | OD 6-630mm

WT 0.5-28mm |

GB/T14975-2002 |

| 00Cr19Ni10 | 304L/S30403 | SUS304L | X2CrNi19-11 | 1.4306 | GB/T14976-2002 | ||

| 00Cr25Ni20 | 310S/31008 | SUS310S | X12CrNi25-21 | 1.4845 | GB13296-91 | ||

| 0Cr17Ni12Mo2 | 316/S31600 | SUS316 | X5CrNiMo17-12-2 | 1.4401 | |||

| 00Cr17Ni14Mo2 | 316L/S31603 | SUS316L | X2CrNiMo18-14-3 | 1.4435 | ASTM A213/A213M | ||

| 0Cr19Ni13Mo3 | 317/S31700 | SUS317 | X5CrNiMo11-13-3 | 1.4449 | ASTM A312/312M | ||

| 00Cr19Ni13Mo3 | 317S/S31703 | SUS317L | X2CrNiMo18-16-4 | 1.4438 | JIS G3459 | ||

| 1Cr18Ni9Ti | 321/S32100 | SUS321 | X12CrNiTi18-9 | 1.4878 | DIN2462 | ||

| 0Cr18Ni10Ti | X6CrNiTi18-10 | 1.4541 | |||||

| 0Cr18Ni11Nb | 347/S34700 | SUS347 | X12CrNiNb18-10 | 1.4550 | |||

| Item No. | Steel Grades | Main Steel Codes |

| 1 | Austenite | 301, 310S, 304, 316, 316L, 316Ti, 317, 321, 347H, 904L |

| 2 | Ferrite | 430 |

| 3 | Bio-phase | S31803, S2205 |

304, 304L, 316, 316L are the four most popular austenitic grades of stainless steel piping which provide excellent corrosion resistance.

Material is stocked in the annealed and pickled, bright annealed, mill finish and polished conditions.