09CrCrSb(ND) SEAMLESS STEEL TUBE FOR ANTI-ACID LOW TEMPERATURE DEW POINT CORROSION

ND steel is one new-style low alloy structural steel. Compared with other steel, like low carbon steel, Corten, CR1A, ND steel has excellent corrosion resistance and mechanical properties. The results show that in the aqueous solution of vitriol, hydrochloric acid and sodium chloride, the corrosion resistance of ND steel is higher than carbon steel. The most prominent feature is that it has strong ability of anti-acid dew point corrosion. From indoor temperature to 500℃, the mechanical property of ND steel is higher than carbon steel and steady, the welding property is excellent. ND steel is usually used to manufacture economizer, heat exchanger and air heater. From 1990s, ND steel is widely used in the industries of petrifaction and electric power.

09CrCuSb (ND steel) resistant to sulfuric acid low temperature dew point corrosion steel (ND steel, ND steel, 09CrCuSb steel, 09CrCuSb steel, etc.). Usually called 09 club.

09CrCuSb (ie ND steel) Standard:

Q/TDGG0039-2004—–Industry internal standard

GB 150.2-2011 – Pressure Vessels Part 2

09CrCuSb (ie ND steel) Grade:

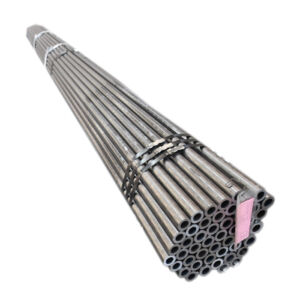

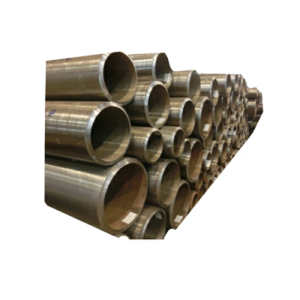

09CrCuSb (ND steel pipe)

09CrCuSb (ie ND steel) Chemical Composition:

|

Grade |

Chemical Composition(%) |

|||||||

| C | Si | Mn | Cr | Cu | Sb | P | S | |

| 09CrCusb | ≤0.10 | 0.20-0.40 | 0.35-0.65 | 0.70-1.20 | 0.25-0.45 | ≤0.10 | ≤0.10 | ≤0.10 |

09CrCuSb (ie ND steel) Mechanical Properties:

|

Grade |

Tenslle Strength(MPa) | Yield Strength(MPa) | Elongation(%) |

|

09CrCuSb |

390-550 | ≥245 |

≥25 |

09CrCuSb (ie ND steel) Chemical composition in GB 150.2-2011:

|

09CrCuSb |

|||||||

| C | Si | Mn | P | S | Cr | Cu |

Sb |

|

≤0.12 |

0.20~0.40 | 0.35~0.65 | ≤0.030 | ≤0.020 | 0.70~1.10 | 0.25~0.45 |

0.04~0.10 |

Comparison of corrosion rate between ND steel and other steel grades (70 ℃ – 50% H2SO4 solution)

| Steel Grade | 09CrCuSb(ND steel) | CRIR(Japan) | 1Cr18Ni9 | Corten | STEN(Japan) |

A3(Q235B) |

|

Corrosion rate |

7.30 | 13.40 | 21.70 | 63.00 | 27.4 | 103.50 |

| multiple | 1 | 1.84 | 2.97 | 8.63 | 3.75 |

14.11 |

09CrCuSb (ie ND steel) Specification:

|

Specification |

Specification |

|

19*2-4mm |

76-114 * 4-10mm |

|

25 * 2-4mm |

133-140 * 6-14mm |

|

32 * 2-5mm |

159-219 * 21-35mm |

|

38-42 * 3-5mm |

273-325 * 7-50mm |

| 51-63 * 3-5mm |

356-630 * 10-20mm |

09CrCuSb (ND steel) steel is developed for coal-fired boilers, oil-fired boilers; heat exchangers for electric furnaces, pipes, chimneys, boiler air preheaters, economizers, heat exchangers, condensing coolers, evaporators, etc. Hot-rolled steel sheets and steel pipes with excellent resistance to sulfuric acid dew corrosion. Its superior resistance to sulfuric acid dew point corrosion and very high cost performance is the best material that can completely replace stainless steel and surpass stainless steel (in terms of sulfuric acid dew point corrosion resistance). ND steel has great economic significance, in line with today’s high efficiency, longevity and energy saving. “Green” concepts such as environmental protection and national development policy orientation.

Advantage of 09CrCuSb (ND steel):

ND steel, 09CrCuSb steel, is the most ideal steel for “sulfuric acid resistant low temperature dew point corrosion” at home and abroad. ND steel is widely used in the manufacture of economizers, air preheaters, heat exchangers and in high sulfur flue gas. Equipment such as evaporators, used to resist corrosion of sulfur-containing flue gas dew point. ND steel also has the ability to resist chloride ion corrosion. The main reference index of ND steel pipe (soaked in 50% H2SO4 solution at 70 °C for 24 hours) is higher than that of carbon steel and stainless steel.

Application of 09CrCuSb (ND steel):