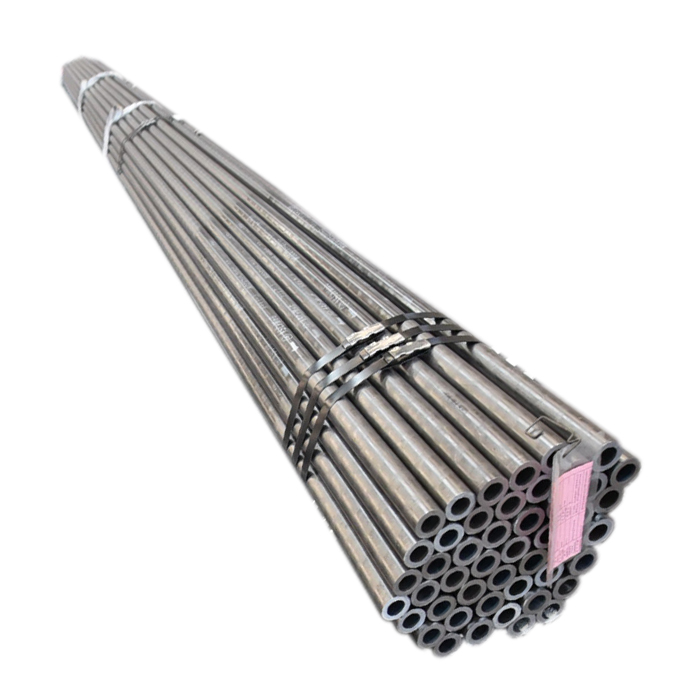

ASTM A213 / A213M T2, T5, T5b, T9, T91 SEAMLESS ALLOY STEEL BOILER, SUPERHEATER, AND HEAT-EXCHANGER TUBES

ASTM A213 / A213M ASME SA213 tubes shall be made by the seamless process and shall be either hot-finished or cold finished as specified.

ASTM A213 / A213M covers several grades of minimum- wall-thickness, seamless, alloy-steel, boiler and superheater tubes.

ASTM A213 / A213M tubing sizes and thicknesses usually furnished to this specification are 1⁄8 in. [3.2 mm] in inside diameter to 5 in. [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness or, if specified in the order, average wall thickness. Tubing having other diameters may be furnished, provided such tubes comply with all other requirements of this specification.

Standard: ASTM A213 / A213M, ASME SA213.

ASTM A213 / ASME SA213 T5 Seamless tubes, ASTM A213 / ASME SA213 T5b Seamless tubes, ASTM A213 / ASME SA213 T9 Seamless tubes, ASTM A213 / ASME SA213 T91 Seamless tubes, ASTM A213 / ASME SA213 T5 Seamless alloy tubes, ASTM A213 T5b Superheater tubes, ASTM A213 T9 Superheater tubes, ASTM A213 T91 Superheater tubes, ASTM A213 T5 boiler tubes, ASTM A213 T5b boiler tubes, ASTM A213 T9 boiler tubes, ASTM A213 T91 boiler tubes, ASTM A213 / ASME SA213 T2 Seamless tubes, ASTM A213 / ASME SA213 T2 Seamless alloy tubes, ASTM A213 T2 Superheater tubes, ASTM A213 T2 boiler tubes, Seamless superheater tubes, Boiler tubes.

Size: 3.2 to 127 mm.

Wall Thickness: 0.4 to 12.7mm.

Shape: Round.

Length: Single random length/ Double random length or as customer’s actual request.

Grade: T2, T5, T5b, T9, T91.

Referenced Documents:

ASTM A 1016/A 1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stain- less Steel Tubes.

Chemical Composition:

| Chemical Components (%) | ||||||||||||

| Grade | C | Mn | P | S | Si | Cr | Mo | V | Nb | N | Al | others |

| T2 | 0.10-0.20 | 0.30-0.61 | ≤0.025 | ≤0.025 | 0.10-0.30 | 0.50-0.81 | 0.44-0.65 | |||||

| T5 | 0.15 | 0.30-0.60 | ≤0.025 | ≤0.025 | 0.5 | 4.0-6.0 | 0.45-0.65 | |||||

| T5b | 0.15 | 0.30-0.60 | ≤0.025 | ≤0.025 | 1.0-2.0 | 4.0-6.0 | 0.45-0.65 | |||||

| T9 | 0.15 | 0.30-0.60 | ≤0.025 | ≤0.025 | 0.25-1.0 | 8.0-10.0 | 0.90-1.10 | |||||

| T91 | 0.07-0.14 | 0.30-0.60 | ≤0.020 | ≤0.010 | 0.20-0.50 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.06-0.1 | 0.030-0.070 | 0.02 | Ti 0.01 Zr 0.01 |

Heat Treatment Requirements

| Grade | UNS Number | Heat Treat Type | Austenitizing / Solutioning Temperature, min or range °F [°C] | Subcritical Annealing or Tempering Temperature, Min or range °F [°C] |

| T2 | K11547 | full or isothermal anneal normalize and temper subcritical anneal | … | 1200 to 1350

[650 to 730] |

| T5 | K41545 | full or isothermal anneal normalize and temper | … | 1250 [675] |

| T5b | K51545 | full or isothermal anneal normalize and temper | … | 1250 [675] |

| T9 | K50400 | full or isothermal anneal normalize and temper | … | 1250 [675] |

| T91 | K90901 | normalize and temper | 1900–1975 [1040–1080] | 1350–1470 [730–800] |

Tensile Requirements and Hardness:

| Mechanical Properties | ||||

| Grade | Tensile | Yield | Elongation | Hardness |

| Strength (Mpa) | Strength (Mpa) | (%) | ||

| T5b | ≥415 | ≥205 | ≥30 | ≤89HRB |

| T9 | ≥415 | ≥205 | ≥30 | ≤89HRB |

| T91 | ≥585 | ≥415 | ≥20 | ≤25HRC |

Flattening Test – One flattening test shall be made on specimens from each end of one finished tube, not the one used for the flaring test, from each lot.

Flaring Test – One flaring test shall be made on specimens from each end of one finished tube, not the one used for the flattening test, from each lot.

Hydrostatic or Nondestructive Electric Test – Each tube shall be subjected to the nondestructive electric test or the hydrostatic test. The type of test to be used shall be at the option of the manufacturer, unless otherwise specified in the purchase order.

Materials and Manufacture:

The Steel shall be killed.

The Tubes shall be made by the seamless process and shall be either hot-finished or cold finished, as specified.

Heat Treatment

Ferritic Alloy and Ferritic Stainless Steels – The ferritic alloy and ferritic stainless steels shall be reheated for heat treatment in accordance with the requirements of Standard. Heat treatment shall be carried out separately and in addition to heating for hot forming.

Note:

Mill test certificates will be issued according to EN10204.3.

All tubes shall be supplied as per applicable ASTM A213 /A213M Specification.