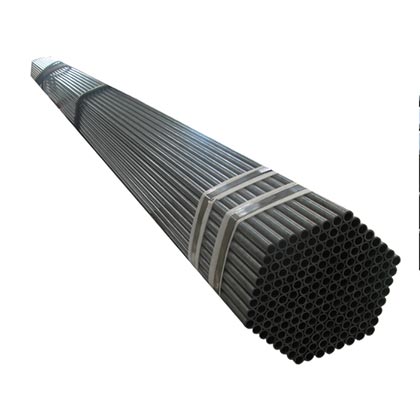

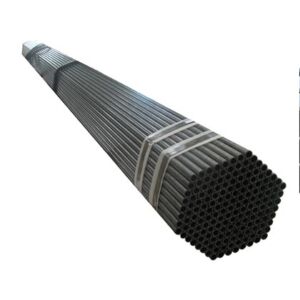

ASTM A179 ASME SA179 Seamless Low Carbon Steel Tube For Heat Exchanger

Carbon steel tubes are heat treated after the final cold draw pass at a temperature of 1200℉(650℃) or higher, used for Mechanical purposes, involving machining or heat treatment, to reach good tolerance, smooth surface, good perfromace on Mechanical properties.

Standard : ASTM A179 /ASME SA179

Size Range: O.D.:6-114mm W.T.:1-15mm L: max 12m

Surface: Oil-dip, Varnish,ect

Material: Low Carbon Steel

Production: Seamless Cold Drawn

ASTM A179 ASME SA179 Carbon Steel Tube Chemical Composition (%)

|

C |

Mn | P≤ | S≤ | Si≤ |

|

0.06-0.18 |

0.27-0.63 | 0.035 | 0.035 | 0.25 |

ASTM A179 ASME SA179 Carbon Steel Tube Mechanical properties

|

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

Elongation (%) |

|

≥180 |

≥325 |

≥35 |

Delivery Conditions:

- Annealed, Normalized, Normalized and Tempered

- Mill test certificates will be issued according to EN10204 3

- Packing: packed in wooden crates, wrapped in plastic, and suitably protected for sea-worthly delivery or as requested.

- Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles.

Inspection and Test: Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test.

Application: U bend Tubes according to Customer request. ASTM A179 seamless low carbon steel tube is for tubular heat exchangers,condensers,and similar heat transfer apparatuses ,also used for Boilers,Superheaters ,Shell & Tube Heat Exchangers,Feedwater Heaters,Condensers,Evaporators.U bend tubes for heat exchangers applied mostly in oil and gas plants, chemical and petrochemical plants, refineries, power plants and renewable energy plants. Low fin tubes can be supplied in the form of U bends.