Welded Stainless Steel Pipe/ Tubo soldado de acero inoxidable

Welded stainless steel pipe is usually made of stainless steel plate or steel strip after rolling and forming by machine and mould.

Application: Welded stainless steel pipe is widely used in oil refining, petrochemical, electric power, paper making, liquor making, automobile, electronic technology, biochemical technology, environmental engineering and other industries.

Main Standard: ASTM A312, ASTM A269, ASTM A249, ASTM A554

Main Grade: 304, 304L, 316L, 321, 310S, 904L, 2205; 1.4301, 1.4306, 1.4404, 1.4541, 1.4845, 1.4539

Outer Diameter: 9.5-2000mm

Wall Thickness: 1.0-30mm

Length: fixed 6m or as customers’ requirement

Surface Treatment: pickling or as customers’ requirement

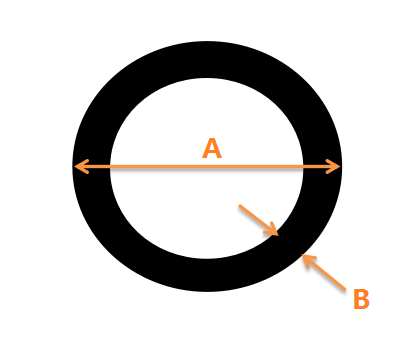

How is it Measured? Outer Diameter (A) X Schedule or Wall Thickness (B) X Length

PS: Advantages Of Welded Tubes & Pipes

A. Lower cost compared to the equivalent seamless alternative

B. Short lead time

C. Better surface finishing of outside and inside, the internal material surface for welded tubes can be checked prior to manufacture

D. Thinner wall thickness and more uniform

E. Tighter tolerance

|

Type |

Grade of Steel | Size | Standard | ||||

| GB | ASTM | JIS |

Germany |

||||

|

DIN17006 |

DIN17007 | ||||||

| Welded Stainless Steel Pipe | 0Cr18Ni9 | 304/S30400 | SUS304 | X5CrNi18-10 | 1.4301 | OD 19-1000mm

WT 1-20mm |

GB/T12770-91 |

|

00Cr19Ni10 |

304L/S30403 | SUS304L | X2CrNi19-11 | 1.4306 | GB/T12771-2000 | ||

| 00Cr25Ni20 | 310S/31008 | SUS310S | X12CrNi25-21 | 1.4845 |

HG20537.2-92 |

||

|

0Cr17Ni12Mo2 |

316/S31600 | SUS316 | X5CrNiMo17-12-2 | 1.4401 | HG20537.3-92 | ||

| 00Cr17Ni14Mo2 | 316L/S31603 | SUS316L | X2CrNiMo18-14-3 | 1.4435 |

HG20537.4-92 |

||

|

0Cr19Ni13Mo3 |

317/S31700 | SUS317 | X5CrNiMo11-13-3 | 1.4449 | |||

| 00Cr19Ni13Mo3 | 317S/S31703 | SUS317L | X2CrNiMo18-16-4 | 1.4438 |

ASTM A312/A312M |

||

|

1Cr18Ni9Ti |

321/S32100 | SUS321 | X12CrNiTi18-9 | 1.4878 | ASTM A688/A688M | ||

| 0Cr18Ni10Ti | X6CrNiTi18-10 | 1.4541 |

JIS G3468 |

||||

|

0Cr18Ni11Nb |

347/S34700 | SUS347 | X12CrNiNb18-10 | 1.4550 |

DIN 2462 |

||

| Item No. | Steel Grades | Main Steel Codes |

| 1 | Austenite | 301, 310S, 304, 316, 316L, 316Ti, 317, 321, 347H, 904L |

| 2 | Ferrite | 430 |

| 3 | Bio-phase | S31803, S2205 |

304, 304L, 316, 316L are the four most popular austenitic grades of stainless steel piping which provide excellent corrosion resistance.

Material is stocked in the annealed and pickled, bright annealed, mill finish and polished conditions.

How to select welded stainless steel pipe?

The quality of steel pipe is mainly measured by the same material, standard and welding quality.

According to its own structural characteristics, stainless steel straight welded pipe has two main uses:

First, it is used to transport liquids, such as water supply and drainage;

Secondly, based on the superior anti-corrosion performance of welded straight seam stainless steel pipe, it can also be used to transport gas, oil and other chemicals.

We use SUS304 and SUS316 materials, superior performance, products with good pressure resistance, corrosion resistance, health and environmental protection. The products meet the requirements of ASTM A554, ASTM A312, EN10312, JIS G3448 and other standards. It is widely used in cold water heating system of industrial and civil buildings, heat exchange system and pipeline system of environmental protection, energy and petrochemical industry. From the acquisition of raw materials, from the production process to production testing, we have a complete process. Our products are widely used in hotels, natural gas, municipal, fire, food, cruise, construction and other projects.