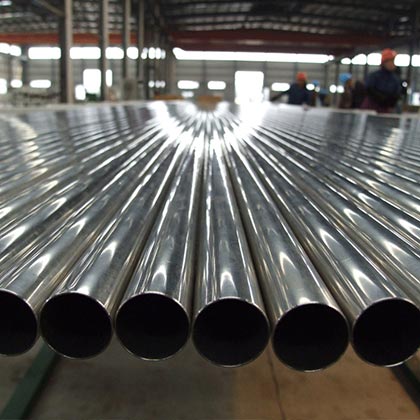

Sanitary Stainless Steel Welded Tubing/ Tubos soldados de acero inoxidable sanitario

Generally, sanitary grade welded tubes have strict regulations on chromium, nickel, sulfur and carbon content, and have higher requirements for polishing degree.

Application: Sanitary stainless steel pipe is mainly used in food, beverage, alcohol, bioengineering and other production equipment and assembly lines.

Main Standard: ASTM A270; JIS G3447

Main Grade: 304, 316L; 1.4301, 1.4404

Outer Diameter: 16-325mm

Wall Thickness: 1.2-4mm

Length: fixed 6m or as customers’ requirement

Surface Treatment: polishing or as customers’ requirement

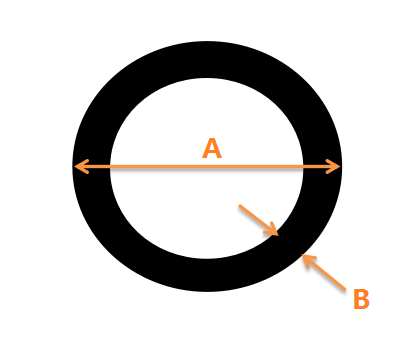

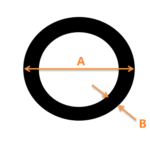

How is it Measured? Outer Diameter (A) X Schedule or Wall Thickness (B) X Length

PS: 304 VS 316L

| 304 benefits | 316L benefits |

| Lower cost | Superior corrosion |

| Easier to weld and form | Stronger and more durable |

| Able to withstand corrosion from most oxidizing acids | Better for marine, offshore and washdown applications |

Advantages Of Welded Tubes & Pipes

A. Lower cost compared to the equivalent seamless alternative

B. Short lead time

C. Better surface finishing of outside and inside, the internal material surface for welded tubes can be checked prior to manufacture

D. Thinner wall thickness and more uniform

E. Tighter tolerance