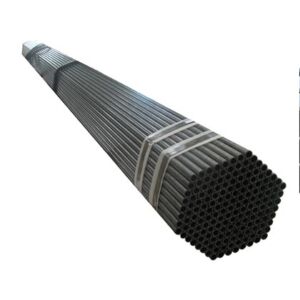

JIS G3461 STB 340 Boiler and Heat Exchanger Tubes

Standard: JIS G3461 Carbon Steel Tubes for Boiler and Heat Exchanger

JIS G3461 STB 340 specifies the carbon steel tubes, hereinafter referred to as the “tubes”, used for exchanging heat on the inside and outside of the tube, such as water tubes, smoke tubes, superheater tubes, air preheater tubes, etc. of the boiler, and heat exchanger tubes, condenser tubes, catalyzer tubes, etc. used in chemical and petroleum industries.

JIS G3461 STB 340 Boiler and Heat Exchanger Tubes Quick Details

Manufacture:Seamless; Electric resistance welded, Cold finished ,Hot finished

Wall thickness(WT): 2.0 mm——12.7 mm.

Outer diameter (OD): 25 mm——139.8 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Method of manufacture

Seamless; Electric resistance welded, Cold finished ,Hot finished

Heat Treatment of JIS G3461 STB 340 Boiler and Heat Exchanger Tubes

| Grade | Heat treatment | ||||

| Hot finished seamless steel tube | Cold finished seamless steel tube | Electric resistance welded steel tube other than hot finished or cold finished steel tube | Finished electric resistance welded steel tube | Fold finished electric resistance welded steel tube | |

| STB 340 | As manufactured, as required, low temperature annealing or normalizing may be performed. | Low temperature annealing,normalizing or full annealing. |

Normalizing | As manufactured. However, as required, low temperature annealing or normalizing may be performed | Normalizing |

Note:The cold finished electric resistance welded steel tube which has been normalized prior to cold finishing may be finished by annealing.

Chemical Composition of JIS G3461 STB 340 Boiler and Heat Exchanger Tubes

|

Standard |

Grade | Chemical Composition Limits (%) | ||||

|

C |

Si | Mn | P |

S |

||

| JIS G3461 | STB 340 | ≤ 0.18 | ≤ 0.3 | 0.30-0.60 | ≤ 0.035 |

≤ 0.035 |

Mechanical Properties of JIS G3461 STB 340 Boiler and Heat Exchanger Tubes

| Grade | Tensile Property (N/mm2) | Yield Point or Yield Strength (N/mm2) | Rockwell hardness HRB | Elongation (%) | ||

| OD ≥20 mm | 10 mm ≤OD <20 mm | OD <10 mm | ||||

| Longitudinal | Transverse | Transverse | ||||

| STB 340 | ≥ 340 | ≥ 175 | 77 max. | ≥ 35 | ≥ 30 | ≥ 27 |

Note:The above table is only applicable for heat exchanger carbon steel tubes. The buyer can appoint the upper limit value of tensile strength. The upper limit value of tensile strength is the above shown value plus 120 N/mm2.

The dimensional tolerances of .JIS G3461 Carbon Steel Tubes for Boiler and Heat Exchanger

Tolerances of Wall Thickness

| Tolerances | Division of wall thickness (mm) |

Division of method of manufacture | Hot finished seamless steel tube | Cold finished seamless steel tube | Electric resistance welded steel tube | |||

| Division of outside diameter (mm) | Under 100 | 100 or over | Under 40 | 40 or over | Under 40 | 40 or over | ||

| Tolerances on wall thickness % | Under 2 | — | — | +0.4mm | +22

0 |

+0.3 | +18

0 |

|

| 0 | 0 | |||||||

| 2 or over to and excl. 2.4 | +40 | — | +20

0 |

+18

0 |

||||

| 0 | ||||||||

| 2.4 or over to or excl. 3.8 | +35 | +35 | ||||||

| 0 | 0 | |||||||

| 3.8 or over to or excl. 4.6 | +33 | +33 | ||||||

| 0 | 0 | |||||||

| 4.6 or over | +28 | +28 | ||||||

| 0 | 0 | |||||||

| Tolerances on thickness disparity% |

— | Within 22.8 of wall thickness | — | — | ||||

Tolerances of Outside Diameter

| Division of outside diameter | Tolerances on outside diamete | |||

| Hot finished seamless steel tube | Cold finished seamless steel tube | Electric resistance welded steel tube other than cold finished | Cold finished electric resistance welded steel tube | |

| Under 25 | +0.4

-0.8 |

【0.10 | 【1.5 | 【0.10 |

| 25 or over to and excl. 40 | 【0.15 | 【0.20 | 【0.15 | |

| 40or over to and excl. 50 | 【0.20 | 【0.25 | 【0.20 | |

| 50 or over to and excl 60 | 【0.25 | 【0.30 | 【0.25 | |

| 60 or over to and excl. 80 | 【0.30 | 【0.40 | 【0.30 | |

| 80 or over to and excl. 100 | 【0.40 | +0.40 | 【0.40 | |

| -0.60 | ||||

| 100 or over to and excl.12 | +0.4

-1.2 |

+0.40 -0.60 |

+0.40 -0.80 |

+0.40 |

| -0.60 | ||||

| 120 or over to and excl.160 | +0.40 -0.80 |

+0.40 -1.00 |

+0.40 | |

| -0.80 | ||||

| 160 or over to and excl.200 | +0.4 | +0.40 | +0.40 | +0.40 |

| -1.8 | -1.20 | -1.20 | -1.20 | |

| 200 or over | +0.4 | +0.40 | +0.40 | +0.40 |

| -2.4 | -1.60 | -1.60 | -1.60 | |

Tolerances of Length

| Division | Tolerance on length | ||

| 50 mm or under in outside diameter |

7 m or under in length | +0.7 mm | |

| 0 | |||

| Over 7 m in length | Add 3 mm to the plus side permissible deviation given above for each increase of 3m or its fraction in length. However, the maximum value shall be 15 mm. | ||

| Over 50 mm in outside diameter |

7 m or under in length | +10mm | |

| 0 | |||

| Over 7 m in length | Add 3 mm to the plus side permissible deviation given above for each increase of 3m or its fraction in length. However, the maximum value shall be 15mm. | ||

Appearance

(1)The tube are practically straight and its both ends shall be at right angles to its axis.

(2)The inside and outside surfaces of the tube are well-finished and free from defects injurious to use.

Testings

(1)Chemical Analysis

(2)Tensile Test

(3)Flattening Test

(4) Flaring Test

(5) Reverse flattening Test

(6)Hydrostatic Test or Nondestructive Examination

Marking

Each tube having passed the inspection shall be marked with the following items. However, the order of arranging the items is not specified. Further, in the case of either smaller tubs or request from the purchaser, the tubes may be bundled together and marked for each bundle by a suitable means.

(1) Class symbol(STB 340)

(2) Letter symbol indication the manufacturing method ()

(3) Dimensions

(4) Manufacturer’s name or its abbreviation

(5) Letter symbol Z indicating the designation of special quality requirements

Note () Symbols for indicating the manufacturing method shall be as follows. However, – may be replaced by a blank.

Hot finished seamless steel tube -S –H

Cold finished seamless steel tube -S –C

Electric resistance welded steel tube other than Hot finished and cold finished -E –G

Hot finished electric resistance welded steel tube -E –H

Cold finished electric resistance welded steel tube -E -C

Report

We will, in general, submit to the purchaser a detailed statement of the test results, method of manufacture, ordered dimensions, quantity, work number indicating the history of manufacture, etc.