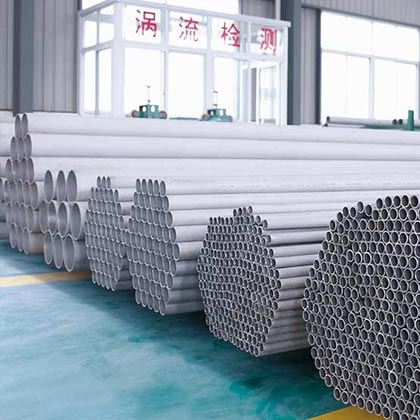

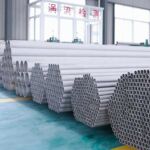

JIS G3459 Stainless Steel Seamless Pipe/ Tubo sin soldadura de acero inoxidable

Seamless stainless steel pipe is made of steel ingot by piercing and then made by hot rolling, cold rolling or cold drawing.

Application: Stainless steel seamless pipe is widely used in boilers, central air conditioning, steel structure, machining, pipeline gas, fire protection, etc.

Main Standard: JIS G3459

Main Grade: SUS304, SUS304L, SUS316L, SUS321

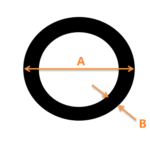

Outer Diameter: 6-325mm

Wall Thickness: 0.5-35mm

Length: Random

Surface Treatment: pickling or as customers’ requirement

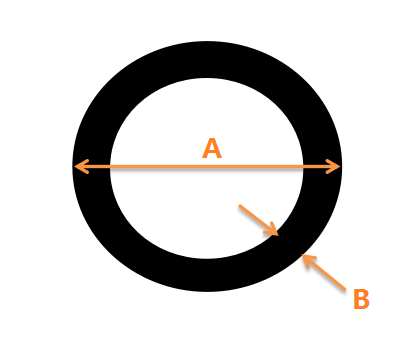

How is it Measured? Outer Diameter (A) X Schedule or Wall Thickness (B) X Length

| 304 stainless steel applications | 316 stainless steel applications |

| Storage tanks | Pharmaceutical equipment |

| Indoor electrical enclosures | Medical equipment |

| Wheel covers | Chemical equipment |

| Automotive trim | Stainless steel floats |

| Kitchen equipment | Structural steel and components in marine environments |

| Appliances | Commercial kitchen surfaces, equipment and appliances |

| Decorative trim |

| 304 benefits | 316L benefits |

| Lower cost | Superior corrosion |

| Easier to weld and form | Stronger and more durable |

| Able to withstand corrosion from most oxidizing acids | Better for marine, offshore and washdown applications |

Advantages Of Seamless Tubes & Pipes

A. Heavy and thick wall thickness

B. No weld seam. Generally be considered as better properties and corrosion resistance

C. Better ovality, or roundness