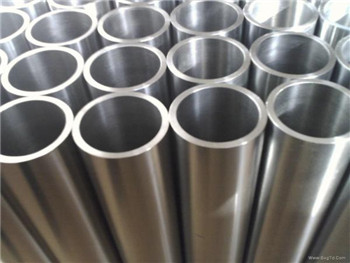

CARBON STEEL PIPE CARBON STEEL TUBE

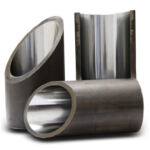

Carbon steel pipes & CARBON STEEL TUBES are low carbon content, better overall performance, and better coordination of strength, plasticity and welding properties. The complex chemical and physical properties of the various grades of carbon steel pipe allow for a broad range of service usage. It ‘s widely used in critical industries where high-temperature and high-pressure conditions are encountered. Carbon steel pipes are mainly used in building structures such as factory buildings, bridges, ships, and general pipelines for conveying fluids.

With the support of the most professional steel manufacturers and a large number of customers, we can not only provide you with ordinary steel but also help you find very personalized steels, such as special steel grades, Special sizes, special craft shapes, etc. Available in a plain bare finish with a light rust protection on the outside only, or in Hot Dipped Galvanised (HDG) with options in plain ends or threaded BSPT or NPT.

As a trusted partner, we have the products you need, when you need them. From full lengths to custom cut pieces, we can handle the job in a timely manner and to your exact requirements. We carry pipe in many different sizes, lengths and specifications. You can find product specs for our welded and seamless steel pipe in our catalogue.

CARBON STEEL PIPE CARBON STEEL TUBE Specifications

| Product | Standard | Grade | OD | THK |

| Structural Tube | ASTM A53 | Gr.A, GR.B, | 13.7-1200mm | 1.5-120mm |

| DIN1629 | ST37, ST44, ST52 | |||

| EN10210-1 | S235JRH, S275JRH, S275J2H, S355J0H, S355J2H, S355K2H | |||

| DIN2440/2441/EN10255 | S195T | |||

| EN10297-1 | E235, E275, E315, E355, E470, C22E, C35E, C45E, C60E, 38Mn6, E275K2, E355K2, E420J2, E460K2, E590K2,E730K2, 41Cr4, 25CrMo4, 30CrMo4, 34CrMo4, 42CrMo4, 36CrNiMo8, 41NiCrMo7-3-2 | |||

| Tube for Liquid Service | ASTM A106 | Gr.A, GR.B, Gr. C | 10.3-1200mm | 1.24-63.5mm |

| ASTM A53 | Gr.A, GR.B, | |||

| Pipe & Tube for Ship Building | CCS, DNV, ABS, LR, BV, KR, NK | Carbon & Carbon-Mangnese | 13.7-609.6mm | 1.0-36.0mm |

| Boiler Tube | DIN17175 | ST35.8, ST45.8, 15Mo3, 13CrMo4, 10CrMo910 | 10.3-711.2mm | 1.24-120mm |

| ASME SA210 | A-1, C | |||

| SA213 | T5, T9, T11, T12, T21, T22, T5b, T9, T91, T92 | |||

| ASME SA333 | G1.1, Gr.6 | |||

| ASME SA335 | P11, P12, P22, P5, P9, P91, P92 | |||

| EN10216-1 | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 | |||

| EN10216-2 | P195GH, P235GH, P265GH, 16Mo3, 13CrMo4-5, 10CrMO9-10, 20MnNb6 | |||

| JIS G3461 | STB340, STB410 | |||

| ASTM A192 | A192 | |||

| ASTM A179 | A179 | |||

| Tubing & Casing | API 5CT | J55, K55,N80-1, N80-Q, L80-1, L80-13Cr, C90-1~2, P110, Q125-1~3 | 1.9″- 20″ | 3.18-22.22mm |

| Drill Pipe | API 5D | E75, X95, G105, S135 | 2 38/”-6 5/8″ | 6.45-19.92mm |

| Line Pipe | API 5L PSL-1/PSL-2 | B, X42, X46, X52, X60, X65, X70, X80 | 10.3-711.2mm | 1.24-63.5mm |

| Mechanical Tube | ASTM A519 | MT1010, 1015, 1020, 1030, 1035, 1040, 1045, 1050, 4130, 4135, 4140, 4145 | 114.3-711.2mm | 6-120mm |

| JIS G3445 | STKM 11A, STKM 12A, STKM 12B, STKM 12C, STKM 13A, STKM 13B, STKM 13C, STKM 14A, STKM 14B, STKM 14C | |||

| Precision Steel Tube | DIN2391/EN10305-1 | E215, E235, E355 | 6-220mm | 0.8-25mm |

| DIN2391/ E10305-4 | E215, E235, E355 | |||

| ASTM A519 | 1008, 1010, 1018, 1020, 1026, 1035, 1045, 4130, 4140 | |||

| DIN2393/EN10305-2 | E155, E195, E235, E275, E355 | |||

| ASTM A513 | 1008, 1010, 1018, 1020, 1026, 1035, 1045, 4130, 4140 | |||

| GOST 8734 | 10 (ST37.0), 20 (ST44.0), 35, 45, 10G2, 15X, 20X, 40X, 30XGCA, 15XM | |||

| GOST 9567 | 10, 20, 35, 45, 40X, 30CrCa |

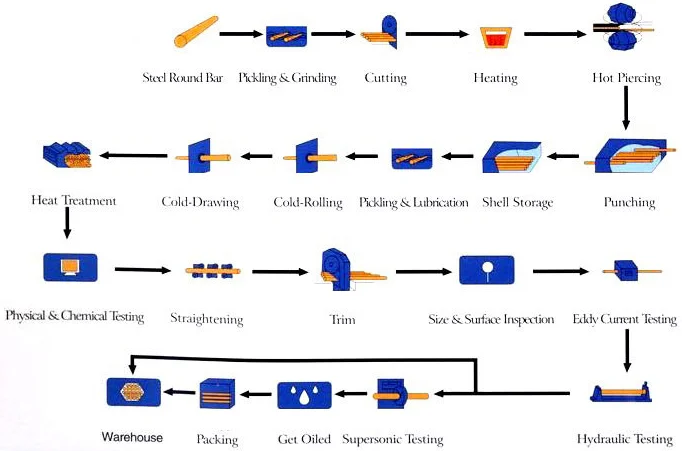

CARBON STEEL PIPE & CARBON STEEL TUBE Production Process

CARBON STEEL PIPE & CARBON STEEL TUBE Inspection

CARBON STEEL PIPE & CARBON STEEL TUBE Packing

- Black Plain End

- Galvanized Plain End

- Threaded and Coupled (Black & Galvanized)

- Victaulic Grooved

- Coated and Wrapped

- Blasted and Primed (O.D. & I.D.)

- Cement Lined

- Concrete Coated

- Fusion Bond Epoxy

- Pickled and Oiled

All the materials we used are ultra-hard and thick, and all the wooden cases and pallets we used are fumigation-free.

- Waterproof Paper Winding+PVC Film+Strap+Wooden Pallet

- Waterproof Paper Winding+PVC Film+Strap+Wooden Case

North Steel adopts standard export shipping packaging and bundles steel strips according to the size of the carbon steel pipe. According to our delivery experience, a 20-foot container can hold 22 tons of carbon steel, and a 40-foot container can hold 25 tons of carbon steel. For larger orders, we use bulk vessels to transport you, and the price is cheaper. Also, we can customize the packaging according to the needs of customers.