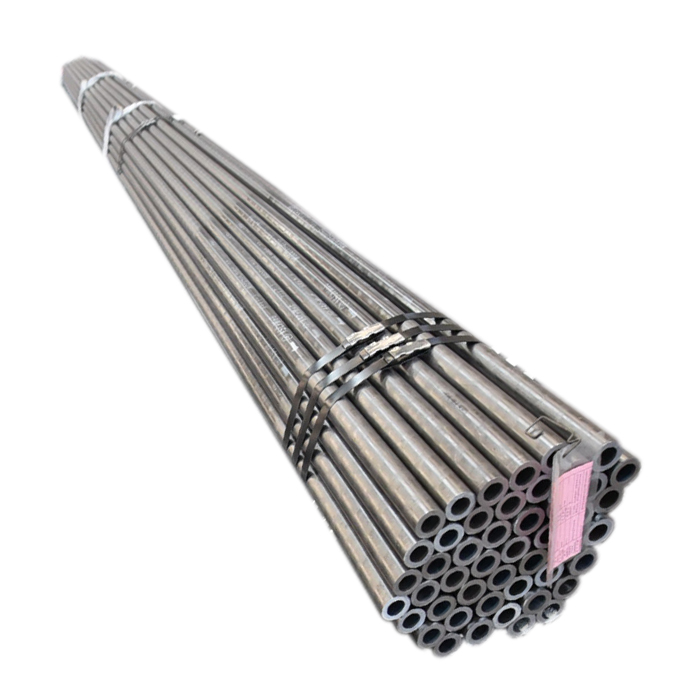

ASTM A192 ASME SA192 Seamless Steel Tube Boiler And Superheater Tubes

Seamless High-pressure Boiler tube including boiler flue tube, superheater tube, steam boiler tube, heat exchanger tube, which work pressure above 9.8MPa, and work temperature between 450℃- 650℃.

Standard: ASTM A192 / ASME SA192

Size Range: O.D.:10-335mm, W.T.:2-25mm, L: 5.8m, 6m, 11.8m, 12m or as customers’ requirment

Surface: varnish paint, anti rust oil, ect

ASTM A192 ASME SA192 Seamless Steel Tube Boiler And Superheater Tubes Chemical Composition

|

Standard |

Grade | C | Si | Mn | P | S |

| ASTM A192

ASME SA192 |

A192 | 0.06-0.18 | ≤ 0.25 | 0.27-0.63 | ≤ 0.035 |

≤ 0.035 |

ASTM A192 ASME SA192 Seamless Steel Tube Boiler And Superheater Tubes Mechanical Properties

|

Yield Strength (Mpa) |

Tensile Strength (Mpa) | Elongation

(%) |

Brinell Hardness Number (WT≥)0.200In(5.1mm) |

Rockwell Hardness Number (WT)0.200In(5.1mm) |

| ≥180 | ≥325 | ≥35 | 137HRB |

77HRB |

ASTM A192 ASME SA192 Seamless Steel Tube Boiler And Superheater Tubes Outside Diameter & Tolerance

|

Hot rolled |

Outside Diameter, mm | Tolerance, mm |

|

OD≤101.6 |

+0.4/-0.8 | |

| 101.6<OD≤177.8 |

+0.4/-1.2 |

|

|

Cold Drawn |

Outside Diameter, mm |

Tolerance, mm |

|

OD<25.4 |

±0.10 | |

|

25.4≤OD≤38.1 |

±0.15 |

|

|

38.1<OD<50.8 |

±0.20 |

|

|

50.8≤OD<63.5 |

±0.25 |

|

|

63.5≤OD<76.2 |

±0.30 |

|

|

76.2≤OD≤101.6 |

±0.38 |

|

| 101.6<OD≤177.8 |

+0.38/-0.64 |

ASTM A192 ASME SA192 Seamless Steel Tube Boiler And Superheater Tubes Wall Thickness & Tolerance

|

Hot Rolled |

Outside Diameter, mm |

Tolerance, % |

|

OD≤101.6, WT≤2.4 |

+40/-0 | |

|

OD≤101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD≤101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD≤101.6, WT>4.6 |

+28/-0 |

|

|

OD>101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD>101.6, 3.8<WT≤4.6 |

+33/-0 |

|

| OD>101.6, WT>4.6 |

+28/-0 |

|

|

Cold Drawn |

Outside Diameter, mm |

Tolerance, % |

|

OD≤38.1 |

+20/-0 |

|

|

OD>38.1 |

+22/-0 |

Features:

★ No leakage under great pressure

★ No oxide layer of inside and outside wall

★ Superior surface finish

★ Flaring, shrinkage and flattening without cracks

Mechanical Tests:

Flattening Test—One flattening test shall be made on specimens from each end of two tubes selected from each lot.

Flaring Test—One flaring test shall be made on specimens from each end of two tubes selected from each lot.

Hardness Test—Brinell or Rockwell hardness tests shall be made on specimens from two tubes from each lot.

Hydrostatic Test—Each tube shall be subjected to the hydrostatic pressure test.

Applications: Cold drawn seamless steel tube SA192 boiler tube is used for boiler application as well as super heater, and heat exchanger industry.