904L Stainless Steel Welded Pipe/ Tubo soldado de acero inoxidable

904L super austenitic stainless steel belongs to low carbon, high nickel and molybdenum austenitic stainless acid resistant steel. It has good activation passivation transformation ability and excellent corrosion resistance. It has good corrosion resistance in non oxidizing acids such as sulfuric acid, acetic acid, formic acid and phosphoric acid, good pitting corrosion resistance in neutral chloride containing medium, and good crevice corrosion resistance and stress corrosion resistance . It is suitable for all kinds of sulfuric acid concentration below 70 ℃. Under normal pressure, it is resistant to acetic acid of any concentration and at any temperature, and it has good corrosion resistance in the mixed acid of formic acid and acetic acid.

Application: 904L stainless steel welded pipe is used for construction, food and medical industry, sewage treatment, petroleum and petrochemical, paper making, power, heat exchanger, condenser, water supply and water supply, military industry, ocean, aerospace, etc

Main Standard: ASTM A312, ASTM A269, ASTM A249, ASTM A554

Main Grade: 904L; 1.4539

Outer Diameter: 16-159mm

Wall Thickness: 1-5mm

Length: fixed 6m or as customers’ requirement

Surface Treatment: pickling or as customers’ requirement

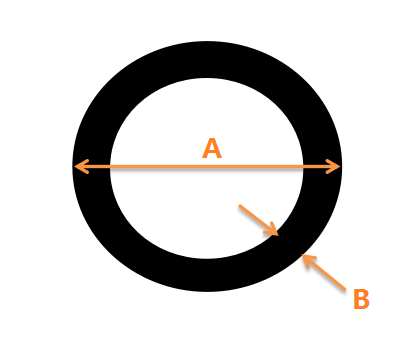

How is it Measured? Outer Diameter (A) X Schedule or Wall Thickness (B) X Length

PS: L in 904L means LOW.

Advantages Of Welded Tubes & Pipes

A. Lower cost compared to the equivalent seamless alternative

B. Short lead time

C. Better surface finishing of outside and inside, the internal material surface for welded tubes can be checked prior to manufacture

D. Thinner wall thickness and more uniform

E. Tighter tolerance