304 Stainless Steel Welded Pipe/ Tubo soldado de acero inoxidable

304 stainless steel welded pipe has the advantages of simple production process, high production efficiency, more varieties and specifications, less equipment and capital, but its compressive strength is generally lower than that of stainless steel seamless pipe.

In recent years, with the rapid development of continuous rolling production of high-quality stainless steel strip and the progress of stainless steel welding and inspection technology, the quality of welding seam is continuously improved, the varieties and specifications of welded stainless steel pipe are increasing, and stainless steel seamless pipe is replaced in more and more fields, especially in heat exchange equipment pipe, decorative pipe, medium and low pressure fluid pipe, etc.

Application: 304 stainless steel welded pipe is used for construction, food and medical industry, sewage treatment, petroleum and petrochemical, paper making, power, heat exchanger, condenser, water supply and water supply, military industry, ocean, aerospace, etc..

Main Standard: ASTM A312, ASTM A269, ASTM A249, ASTM A554

Main Grade: 304; 1.4301

Outer Diameter: 12-3250mm

Wall Thickness: 0.5-45mm

Length: fixed 6m or as customers’ requirement

Surface Treatment: pickling or as customers’ requirement

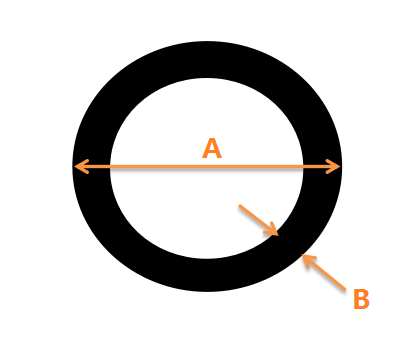

How is it Measured? Outer Diameter (A) X Schedule or Wall Thickness (B) X Length

| 304 stainless steel applications | 316 stainless steel applications |

| Storage tanks | Pharmaceutical equipment |

| Indoor electrical enclosures | Medical equipment |

| Wheel covers | Chemical equipment |

| Automotive trim | Stainless steel floats |

| Kitchen equipment | Structural steel and components in marine environments |

| Appliances | Commercial kitchen surfaces, equipment and appliances |

| Decorative trim |

PS: Advantages Of Welded Tubes & Pipes

A. Lower cost compared to the equivalent seamless alternative

B. Short lead time

C. Better surface finishing of outside and inside, the internal material surface for welded tubes can be checked prior to manufacture

D. Thinner wall thickness and more uniform

E. Tighter tolerance