Surface Finish Grade of Stainless Steel

Original surface: No.1 hot rolled surface after heat treatment and pickling treatment. It is generally used for cold rolling materials, industrial tanks, chemical industrial devices, etc. the thickness ranges from 2.0 mm to 8.0 mm.

Blunt surface: No.2D cold-rolled, heat-treated and pickled, with soft material and silvery white surface, is used for deep stamping, such as automobile components, water pipes, etc.

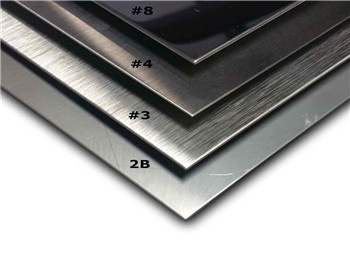

Fog surface: No.2B cold rolled, heat-treated, acid washed, and then finish rolled to make the surface moderately bright. Because the surface is smooth, easy to grind, so that the surface is more bright, widely used, such as tableware, building materials, etc. After adopting surface treatment to improve mechanical properties, it can meet almost all applications.

Coarse sand: No.3 is gritted with 100-120 abrasive belt. It has better gloss and discontinuous coarse grain. Used for interior and exterior decoration materials, electrical products and kitchen equipment.

Fine sand: No.4 is gritted with 150-180 abrasive belt. It has better gloss, discontinuous coarse grain and thinner stripe than No.3. It is used for bath, interior and exterior decoration materials, electrical products, kitchen equipment and food equipment.

No.7 (#320) is gritted with 320 abrasive belt. It has better gloss, discontinuous coarse grain and thinner stripe than No.4. It is used for bath, interior and exterior decoration materials, electrical products, kitchen equipment and food equipment.

Hairline: Hairline No.4 is a product with grinding pattern (subdivided into 150-320) produced by continuous grinding with proper grain size polishing belt. Mainly used for building decoration, elevator, building doors, panels, etc.

Bright surface: BA (Bright Annealed) after cold rolling, bright annealing, and after leveling products. Excellent surface gloss, high reflectivity. Like the surface of a mirror. Used for household appliances, mirrors, kitchen equipment, decorative materials, etc.