Duplex Stainless Steel Welded Pipe/ Tubo soldado de acero inoxidable dúplex

Duplex stainless steel (DSS) refers to the stainless steel with ferrite and austenite accounting for about 50% respectively. Generally, the content of less phases is at least 30%. In the case of low C content, Cr content is 18% ~ 28%, Ni content is 3% ~ 10%. Some steels also contain Mo, Cu, Nb, Ti, N and other alloying elements.

This kind of steel has the characteristics of both austenitic and ferritic stainless steel. Compared with ferrite, this kind of steel has higher plasticity and toughness, no room temperature brittleness, significantly improved intergranular corrosion resistance and weldability. At the same time, it has the characteristics of 475 ℃ brittleness, high thermal conductivity and Superplasticity of ferritic stainless steel. Compared with austenitic stainless steel, it has higher strength and resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent pitting corrosion resistance and is also a kind of nickel saving stainless steel.

Application: Due to its special advantages, duplex stainless steel welded pipe is widely used in petrochemical equipment, seawater and wastewater treatment equipment, oil and gas pipelines, paper machinery and other industrial fields.

Main Standard: ASTM A789

Main Grade: 2205, 2507; 1.4462

Outer Diameter: 5-40mm

Wall Thickness: 0.4-2mm

Length: fixed 6m or as customers’ requirement

Surface Treatment: pickling or as customers’ requirement

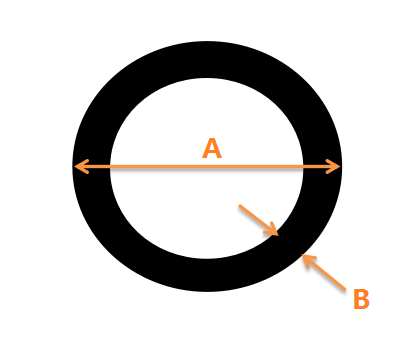

How is it Measured? Outer Diameter (A) X Schedule or Wall Thickness (B) X Length

PS: Advantages Of Welded Tubes & Pipes

A. Lower cost compared to the equivalent seamless alternative

B. Short lead time

C. Better surface finishing of outside and inside, the internal material surface for welded tubes can be checked prior to manufacture

D. Thinner wall thickness and more uniform

E. Tighter tolerance