matel tube

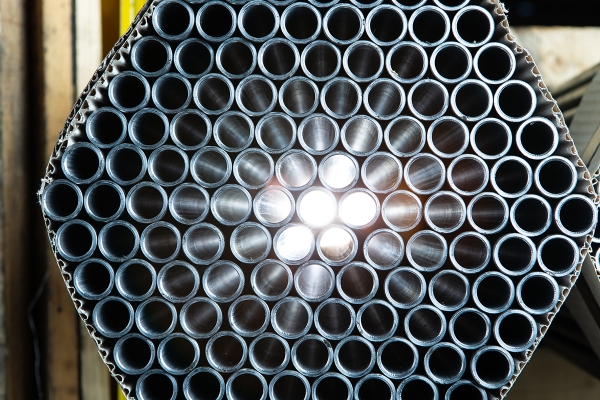

Metal Tube

As an extremely versatile metal shape, metal tubes are used across a variety of industries. Metal tubes are ideal for components used for mechanical projects or equipment. Metal tubes provide different benefits, dependent upon the application and material used for the metal tubes. To help narrow your metal tube search, filter your application specifications by alloy, type, material, thickness, or finish.

Tubing, Round

Tubing, Rectangle

Tubing, Square

Metal tubes are versatile, hollow, cylindrical, or square-shaped products made from materials like steel, stainless steel, aluminum, and titanium, commonly used in structural, mechanical, and architectural applications. Available as seamless, welded, or drawn over a mandrel (DOM), they are specified by outside diameter (OD), inside diameter (ID), and wall thickness. They are ideal for applications requiring high strength-to-mass ratios, such as machinery, automotive parts, and furniture, providing excellent durability and corrosion resistance.

Key Types and Materials

Steel Tubing: Offers exceptional strength, durability, and resistance to bending, used for structural, industrial, and automotive projects.

Stainless Steel Tube: Used for hygienic applications (dairy tubes), handrails, and corrosion-resistant machinery components.

Aluminum Tube: Lightweight and versatile, often used in aerospace, structural, and decorative applications.

Shapes: Round, square, rectangular, and elliptical.

Common Manufacturing Methods

Seamless: Formed without a weld, typically used for high-pressure applications.

Welded: Rolled from sheet/coil and welded, often more economical.

METAL TUBE – Product Information

1. Product Category

– Seamless metal tube

– Welded metal tube

– Round / square / rectangular / special-shaped metal tube

2. Main Materials

– Carbon steel

– Stainless steel (304/316/201, etc.)

– Aluminum alloy

– Copper alloy

3. Standard & Specification

– Standards: AS/NZS, ASTM, DIN, GB, EN, JIS,

– Customizable outer diameter, wall thickness and length

4. Surface Treatment

– Polishing, pickling, galvanizing, painting, anti-rust oil

5. Application

– Machinery manufacturing, construction, fluid transportation, petrochemical, automobile, furniture & decoration

6. Advantage

High precision, good corrosion resistance, stable quality, customizable size, on-time delivery

Carbon Steel AS/NZS 1074, AS/NZS 1163, AS/NZS 1365 Threaded/plain-end, structural,

Stainless Steel AS/NZS 4129, AS 5200.053, AS 3688 Pressure applications, water supply, installation guidelinesABCB

Aluminum Alloy AS/NZS 1866, AS/NZS 1867 Extruded/drawn, chemical composition, mechanical properties

Copper/Alloy AS 1432, AS 1571, AS 1572, AS 3795